Guitar Build Process

Quick links:

Access port cover and frame

Neck block & tongue assembly

Truss rod

Neck, headstock & heel

Headstock veneer

Continuing the neck

Sides

Finishing sides

Back and soundboard

Fitting back and soundboard to sides

Bindings

Fretboard

Fitting neck to body

Making bridge

French polishing soundboard

Complete all construction steps

Installing frets

French polish rest of guitar

Attach bridge

Setup

Hardware information

Build history

Before beginning build

It's a pain when we have to hold up a build while waiting for missing stuff

check that all hardware is in stock or on order:

tuners, fretwire, saddle, nut, strap buttons, stringscheck that adequate timber is in stock:

neck pieces in particular should be well-rested in the workshop

Access port cover and frame

For the cover, there will be six layers, in three pairs

inner pair (smaller hole)

middle pair (larger hole)

outer pair (larger hole, outer layer Blackwood)

For the frame, there will only be four layers (two pairs)

This is because the outer layer will be the sides of the guitar

Resaw & mill tas oak stock into 2.5mm sheets

Do the same for a smaller amount of Blackwood for the outer, show layer

mill this to 2mm, and also a vertical-grain backing layer - to equal thickness of guitar sides

While at it:

consider milling some 2mm fingerboard-wood for pick guard and truss rod cover

consider milling wood for 1 at the same time (1.7x9.5mm?)

Rip stock to required widths before resawing (makes laminating much easier)

Note that the measurements below are workpiece end-targets, leave stock a little wider so that trimming to final size can be done later.

All pieces 2.5mm thick

The 25mm is a minimum, 30 is OK

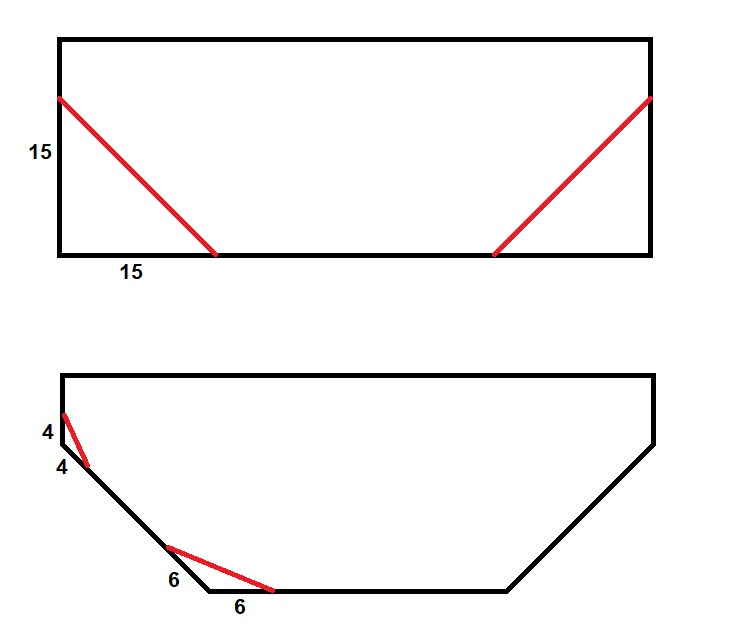

Model |

Bent lengths (2.5mm) |

Straight lengths (2.5mm) |

Bass |

98mm, 106mm, 25mm |

100mm, 125mm, 50mm |

GP |

66mm, 73mm, 25mm |

100mm, 125mm, 50mm |

Parlour |

66mm, 73mm, 25mm |

100mm, 125mm, 50mm |

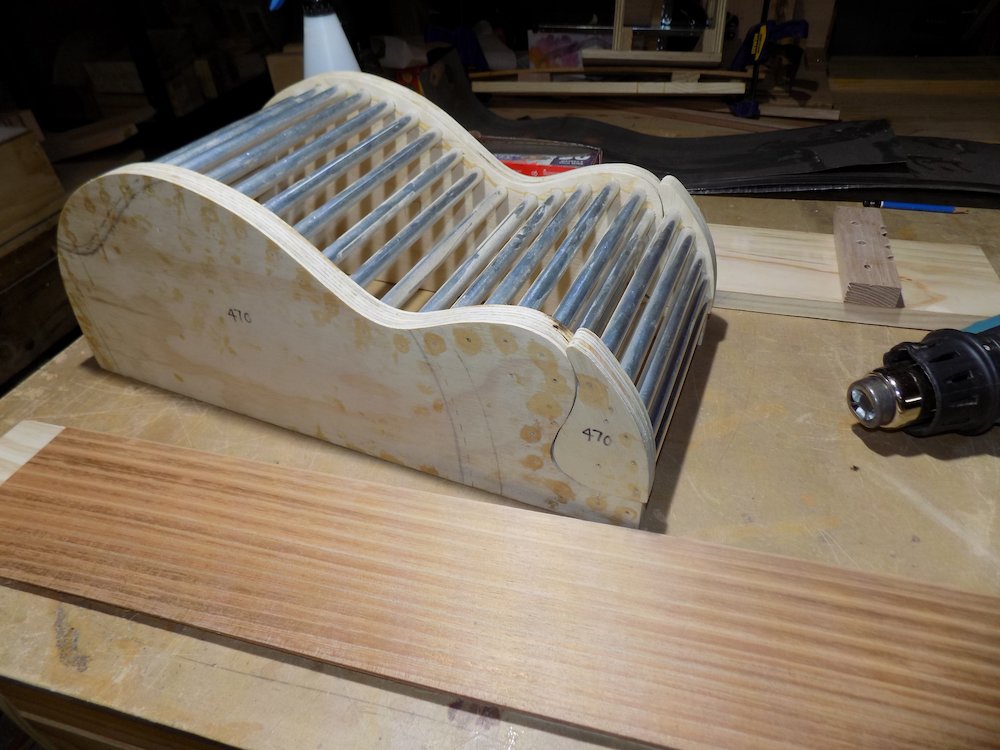

Cut bent stock into 560mm lengths & steam bend

moisten strips, then layer two at a time (for 25++mm widths, two lots side by side)

wrap in aluminium foil

heat with heat gun

place in mould, clamp for 5 mins

swap ends over, re-clamp (try to even out any unevenness in curve)

when cool, remove from mould, remove aluminium foil,

hold lengths in long clamp while drying

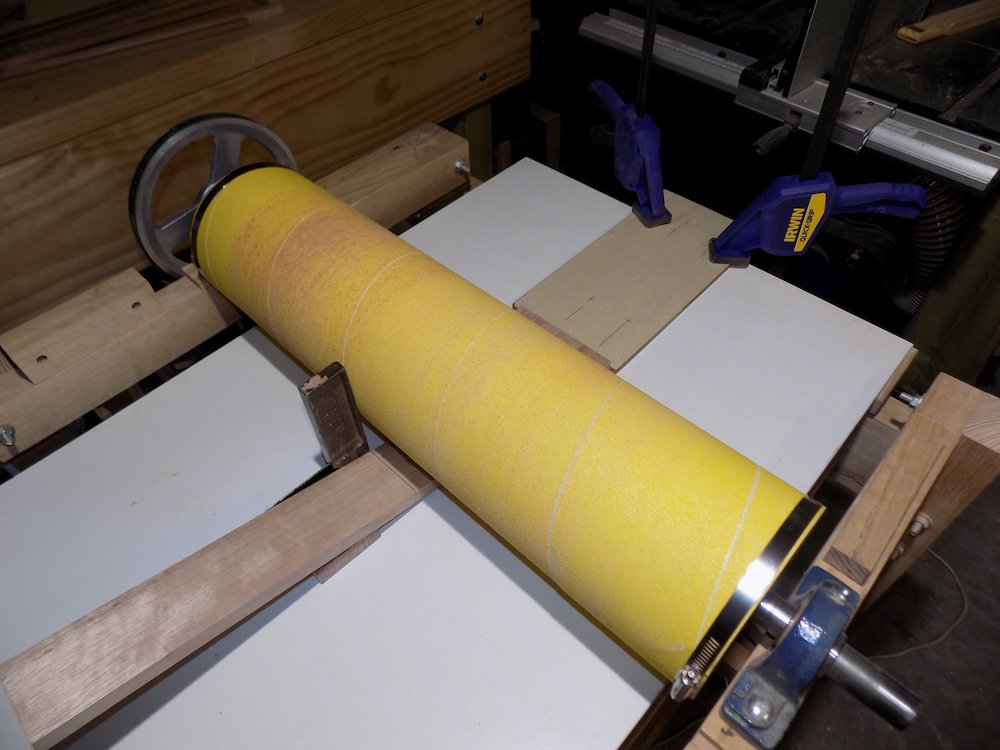

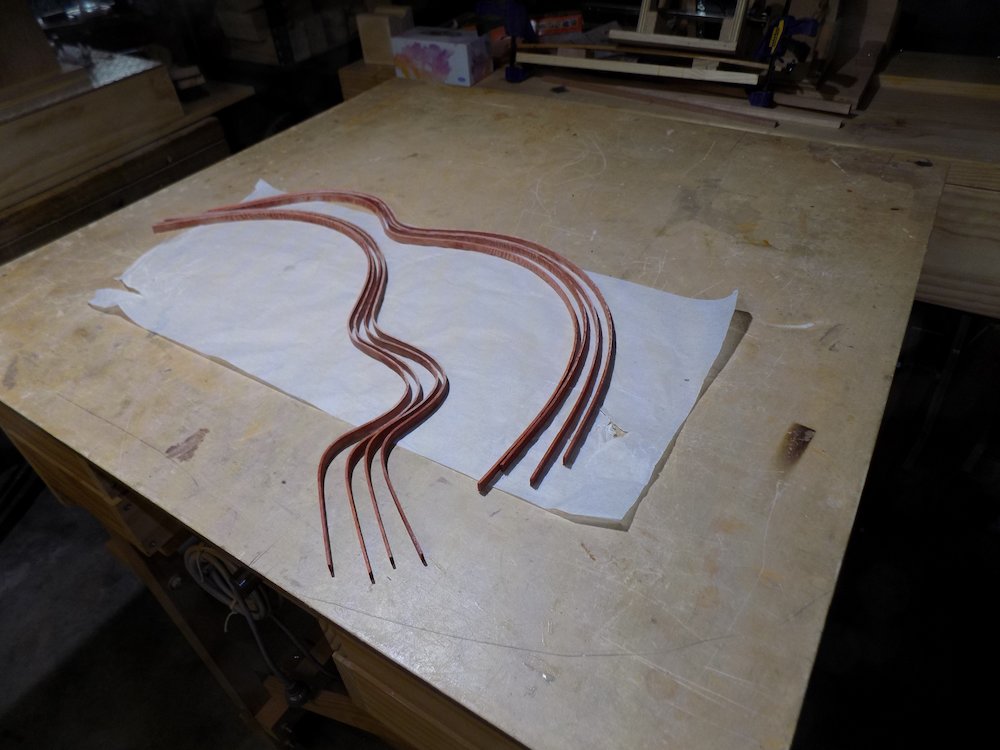

Milled stock |

Applying heat |

Bending in mould |

Drying bent pieces |

Covers

Model |

Inner layer |

Outer layers |

Bass |

100x98mm |

125x106mm |

GP |

100x65mm |

125x73mm |

Parlour |

100x65mm |

125x73mm |

Note that the outermost layer will actually be a little wider due to the "nested" nature of the lamination.

six layers, alternating grain, two "smaller", four "larger" (outer one Blackwood)

laminate in pairs, using bass mould and matching cauls for outer pairs, guitar mould for inner

for each pair, the outer layer has lengthwise grain from bent pieces, inner upright grain from flat.

The outer "show" layer, from 2mm boards, is a little different

may well have both pieces lengthwise grain, as per guitar sides)

we may choose to have Jarrah border on the outermost layer,

in this case, we should wait until it is time to fit the outer layer into the guitar body

The border process is

wait until it is time to fit the outer layer into the guitar body

sand the the outer layer's inner ply to fit

cut the center piece from blackwood, leaving space for border around side

using centre piece to balance vertically, glue in centre piece, top and bottom

glue the side pillars

Trim to dimension/tidiness using belt sander

Then laminate inner and middle pair together:

check curvature of laminating mould against solera mould, with any neck-join shimming in place

tack together with thin nails for alignment,

optional: place nails such that we can clamp around them

otherwise: glue and clamp without moulds, clean off squeeze out,

when confident, remove nails and clamp using moulds(Outer pair will be laminated later)

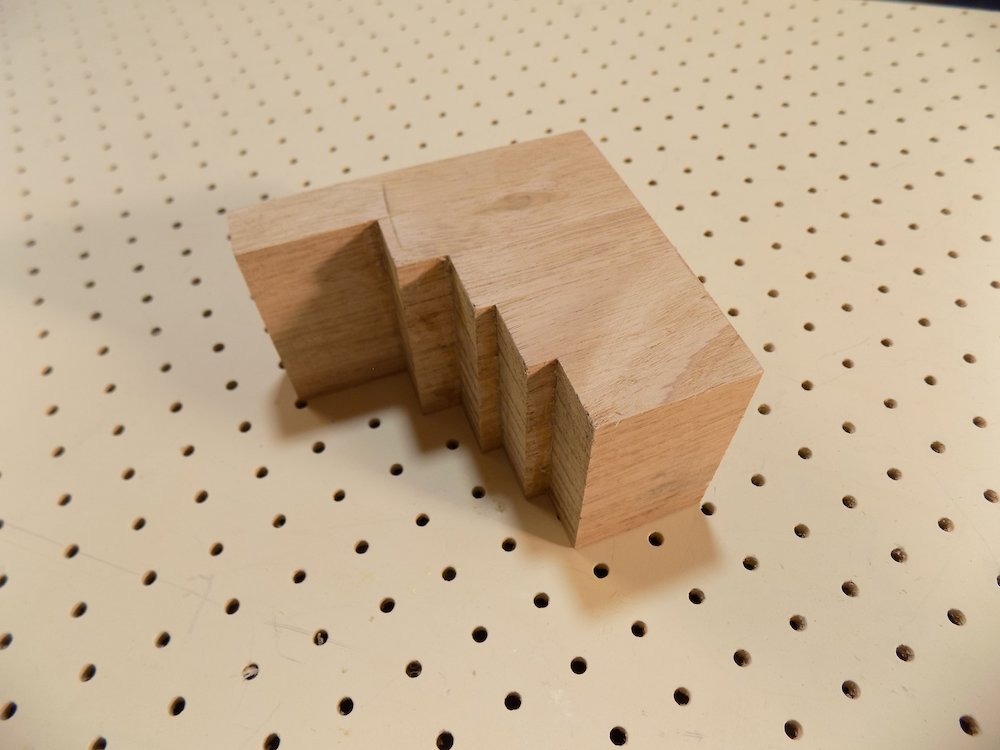

Laminating cover layers |

Cover pieces |

Frames

Dimensions:

frames should be constructed to extend 50mm each side, and 25-30mm top and bottom

frames will be trimmed later, final dimensions determined by guitar sides

Cut all pieces, using laminated cover for measurements

Note that lengths on all curved pieces, and the heights on all straight/vertical pieces, can be rough

Since the two cover pieces were trimmed on the belt sander,

the widths of the vertical pieces will need to be adjusted.

label these pieces to match the corresponding cover edges.

Do all this before gluing (or there'll be some awkward chisel work)!

Laminate the individual pieces, as in access_port.docx diagram below

Notes

For tops and bottoms:

Vertical straight layers are "behind" or "inside", on the concave side

For side pieces:

Vertical straight layers are "in front of" or "outside", on the convex side

In every single case:

Top & bottom have "longer curved pieces"

Sides have "longer straight pieces"

Don't worry about squeeze out from the frame inner edges, that can easily be sanded.

However, do clean up squeeze out from the inner, "stepped" corners (where the shorter piece ends), as this area is a glue face in the next steps.

Acess port layers |

Clamping

Tops and bottoms: can be clamped "as is", as vertical-grain pieces are "thin". However, the access port moulds (and matching cauls) can be used if desired.

Sides: used pairs of small curved cauls, ideally *just* short of the curved-grain widths

Assemble each layer using cover as template,

Separate layers, sand all surfaces so that joins are "flat"

Hold assembled (with covers in place) and trim roughly

Do not glue frame layers together

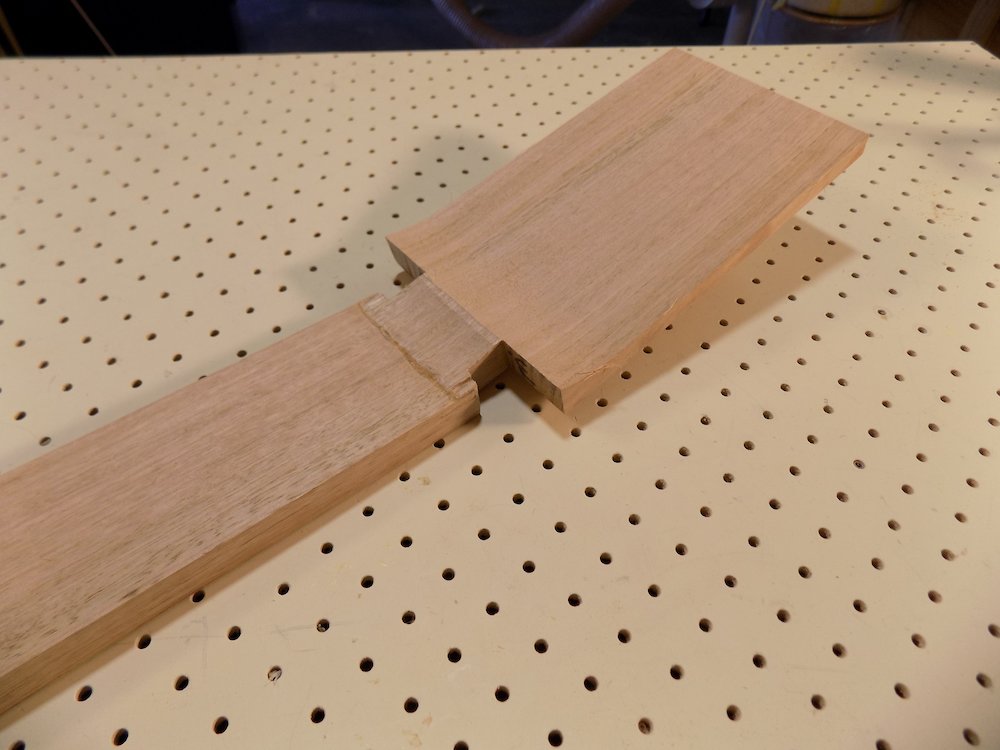

Frame components |

Laminating frame veneers |

Joining frame pieces step 1 |

Joining frame pieces step 2 |

Drill holes in cover and frame

Use regular drill press, Dremel has some vibration issues

1/8" bolts - will use brass nuts and bolts

Using aluminium corner-hole guide, drill first in corners of port cover, from outside inwards

use a sharp drill bit

3mm holes, centres about 6mm in from edges

back with some 13mm scrap on drill platform to get curved surface horizontal

Then drill holes in back layer (of frame) using cover to guide drill (press all layers together)

back with a suitably-thick strip of scrap, to raise workpiece so it hole is level, and also provide clean exit hole

Cut two nut-strips of wood, 4x15

position so they overhang the opening by about 3-4mm

this will support the quite close-to-the-edge hole in the inner layer

Drill 3mm holes in the nut strips, matching those on each side of the port

Enlarge these holes to 5.5mm, but only halfway through (ie, 2mm), on the surface that will be glued to the inside of the frame

Hammer nuts into these holes, so that they are flush with the surface

These are to hold the nuts so they will neither twist, nor be pushed forwards when screwing in access port cover

Do not glue yet - final step requires sides to be completed

Frame pieces trimmed |

Corner hole guide |

Drilling frame |

All access port components |

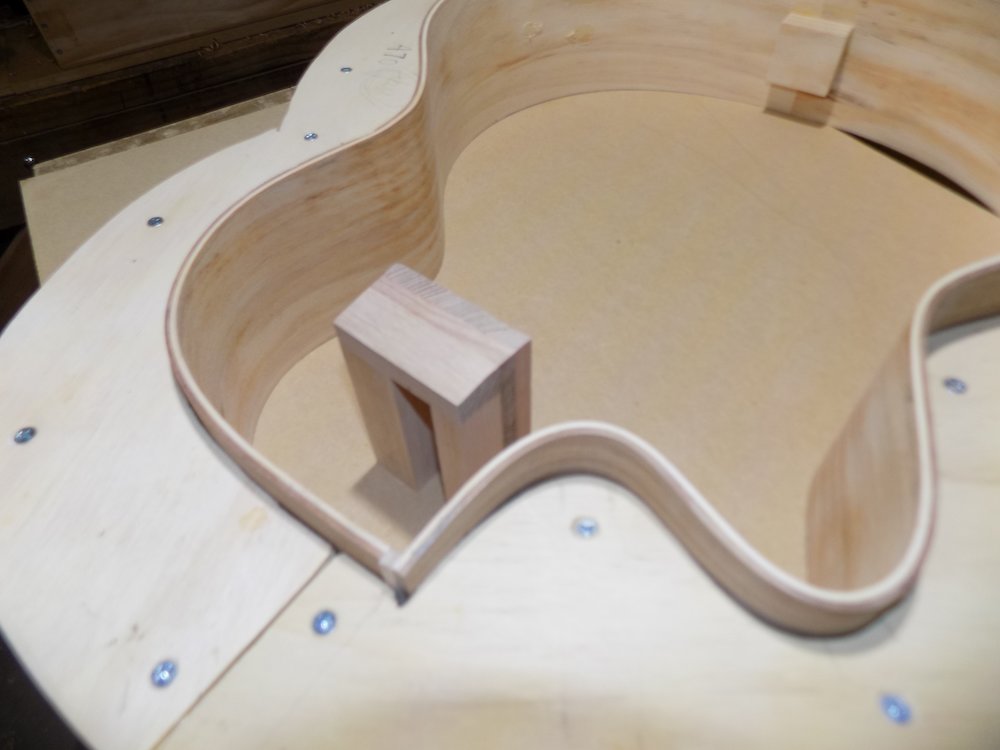

Neck block & tongue assembly

In the following discussion

The term "receiver" refers to the neck block, specifically with respect to its engineered (rather than cut) mortise.

The term "neck tongue" refers to a piece that will eventually be glued into the heel, thereby becoming a tenon

Resaw and mill 19 x 65mm tas oak stock into 8mm stock

two boards can be got from one length

Cross-ply laminate to form receiver backing plate (will need two side-ply pieces butted together)

Bass: |

140++mm |

(neck end dimension 130, but there is an upward ramp) |

GP: |

110++mm |

(neck end dimension 99, ditto) |

Parlour: |

105++mm |

(neck end dimension 94, ditto) |

Trim square after dry

Rip 19mm thickness stock into three pieces per guitar, will form the "receiver" of the neck tongue

NB: each of these measurements are after trimming - can make some of them larger and trim/cleanup

Component |

Bass |

GP |

Parlour |

Base |

65x20 |

65x20 |

65x20 |

Thin upright |

120x19 |

90x19 |

85x19 |

Thick upright |

120x28 |

90x28 |

85x28 |

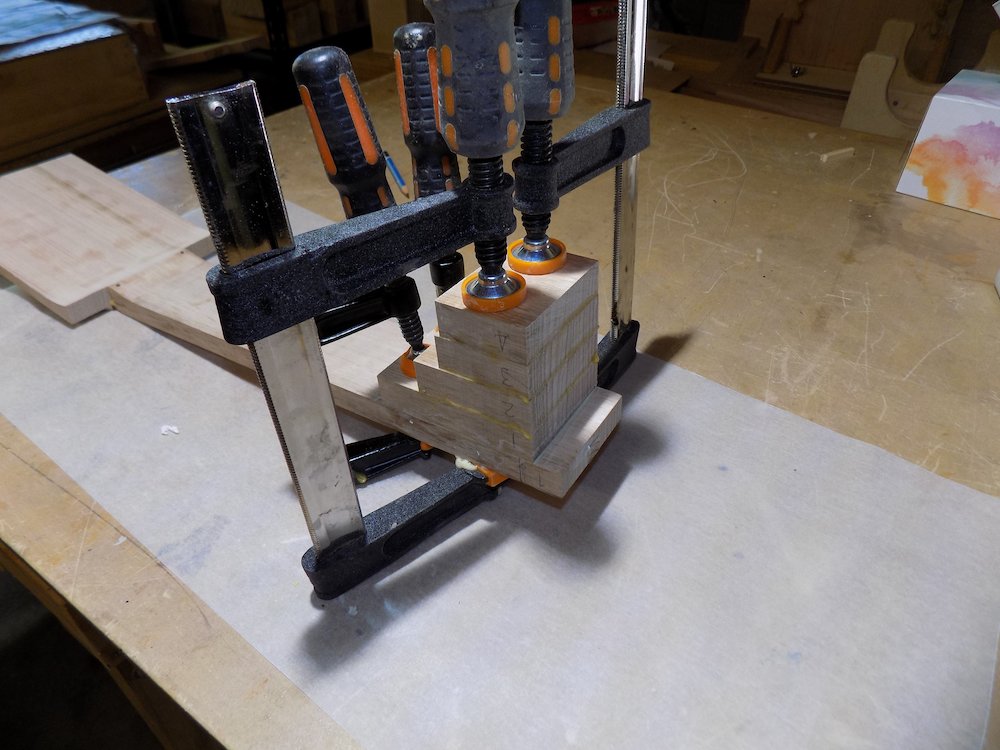

Glue to the cross-grained face of the laminate block,

in the shape of a "U", with the thick piece on the right.

Use the base & thin upright to ensure the channel is perfectly square to the laminated block

slower-but-better: glue it in three steps, bottom, thin, then thick

Use some 19mm waste as a spacer while gluing

Trim/clean up on table saw, round-over the show face (thick upright side)

Neck join tongues

Resaw & mill some 65mm width stock to 5mm and 9mm thickness boards (perhaps even 4 & 11mm)

Component |

Bass |

GP |

Parlour |

Tongue |

115x45 |

85x45 |

80x45 |

two outer layers, grain lengthwise (up & down), 5mm thick

one inner layer, grain sideways (ie inline with as neck), 9mm, will have to butt-join (don't bother with 75/80/110mm wide stock)

laminate, trim, thickness to 19mm using holding channel jig and drum sander if required (minor adjustments can be done using belt sander)

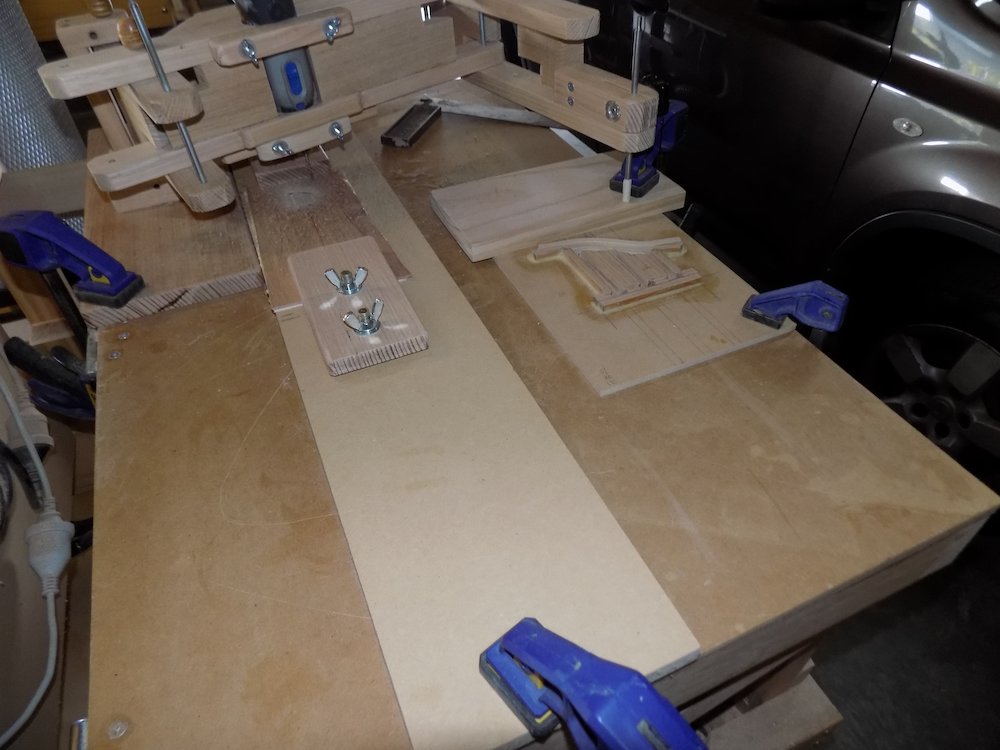

Laminating receiver back plate |

Laminating neck tongue |

Check tongue fit into neck block

NB: Label each side of tongue top/bottom/neck/body

NB: leave some space at the bottom, for vertical adjustability

Choose nuts (need to be set into tongues)

and bolts (need to be 60mm long, and possibly trimmed later

I chose M6 60mm Allen-headed bolts & matching 5mm deep nuts

That means the holes need to be 6mm diameter

Use centering jig to drill two holes in backing plate

measure 15mm from each end of tongue

with tongue centred vertically, mark positions in receiver channel (leave space above and below for adjustment)

a centering jig is a piece of 19mm stock with pilot hole dead centre

insert into receiver, drill holes through pilot hole into backing plate

fit tongue, use holes in backing plate to drill starter holes in tongue

remove tongue from block, finish holes in tongue,

using squaring jig to keep the holes as straight as possible (ie, exit in the centre of the tongue)

Option #1

Bolts are for clamping neck to body, not intended to remain in work

Tidy slots are acceptable aesthetically

Otherwise, consider how to hide/finish off holes after bolts are removed (access will be restricted)

cover strip? channels?

Option #2

Bolts remain in work, useful if tongue requires lots of shimming...

Optionally make an easy-to-fit cover strip (access will be limited, as it will need to be fitted inside the body)

Glue side strips so that centre can be friction-fitted tightly enough to allow glue to cure?

Drill 10mm deep 10mm diam counter-holes in the exit (neck)

Force-fit two nuts into 10mm holes, so they are flush

Note: the inner nut is the only one that will apply tension, the outer is just to prevent it from being knocked forward

Clamp tongue to avoid splitting

Thread one bolt 25mm onto the nut

Use the bolt as a centering guide to hammer the nut into the 10mm hole

Once the nut is just beneath the surface, tap it out, thread the second nut just nestling, not locked, and hammer them both all the way in

Check that the bolts can engage with the nut from the other (body) side

To facilitate fitting the neck, there is one more step

vertically elongate the two holes in the neck block, 2mm top and bottom

very carefully use laminate trimmer/router (low revs), with fence attached to face

This will allow the tongue to slide up and down, and tightened at the correct height

Controlling the router to get tidy slots is difficult, options include

enlarge the holes using a drill first, so that the router can spin freely on startup

before locking the fence, spin the router backwards so that it nudges the work until there is no engagement

use a smaller router bit

|

|

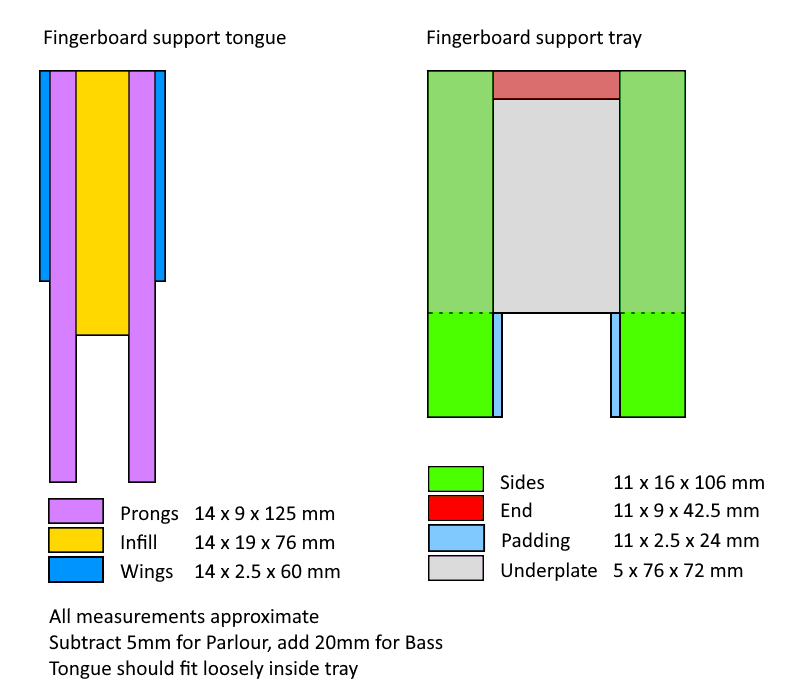

Tentative steps for a bolt-on neck

* construct neck block and neck-tongue as per regualar glued neck, with two exceptions

(a) the top bolt-hole needs to be 12mm lower

(b) don't do the round-over on the wide edge

prepare fingerboard-support components, specifically the 9x14 fork prongs,

a 19x14 inner piece, and two 9x14 wingsThe 14/15mm thickness is for soundboard & soundboard angle, and will be thinned down when fitting neck

Cut off top 11mm of neck block!

Position neck tongue, sticking up

Prepare padding and fingerboard frame pieces, 11mm deep,

leaving an (initially bottomless) pocket 46x{extension}mm

Parlour |

55mm |

GP |

60mm |

Bass |

80mm |

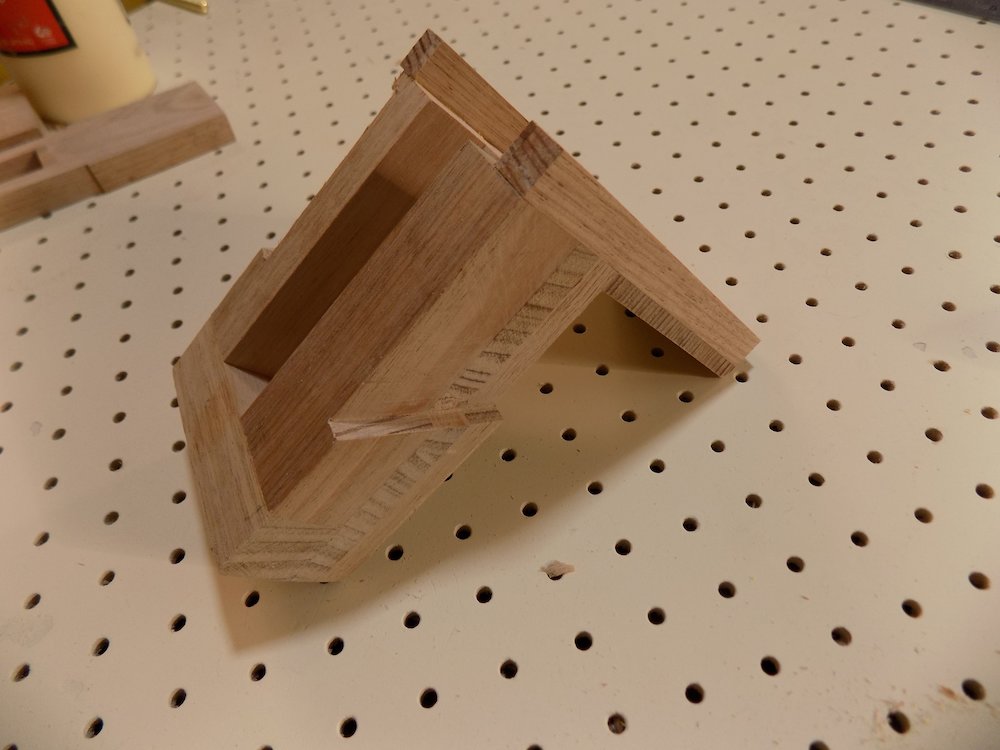

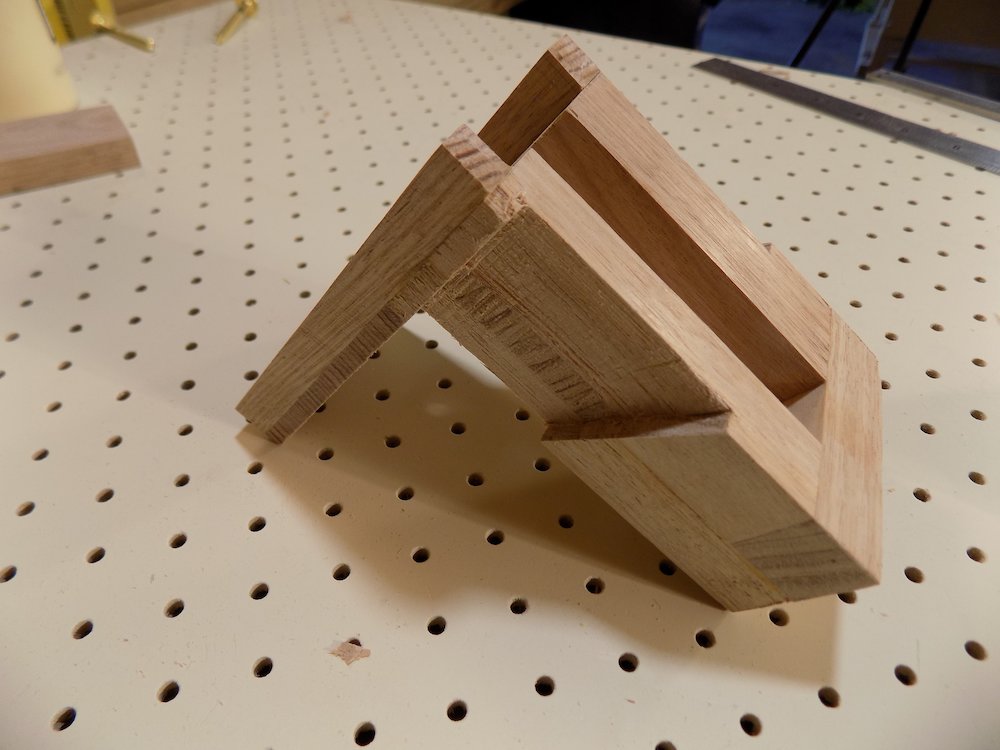

Glue padding and frame together, including the 5mm tray bottom

(Check that top neck-tongue bolts can still be fitted)

Trim the sides so they align with match the neck block, this will mean cutting away 10mm from the cutaway side

Mill some timber to 5mm for the triangular reinforcing side strut-plates

Cut a 5mm triangular support channel into the non-cutaway side of the block

Cut a trapezoid channel on the cutaway side, in just the part beneath the tray underside

In both cases, start at about the midway point between the two bolt holes, up to the end of the underside of the tray

Since the cutaway side is less supported, add a 5mm triangle inside, and a 3mm covering triangle on the outside

Glue the triangular strut-places in flush in place,

angling the grain so that it is parallel with the hypotenuseProceed with build steps until it is time to fit neck

Fingerboard support pieces |

Reinforcing recess, non-cutaway side |

Reinforcing recess, cutaway side |

Reinforcing pieces |

Bolt-on neck components |

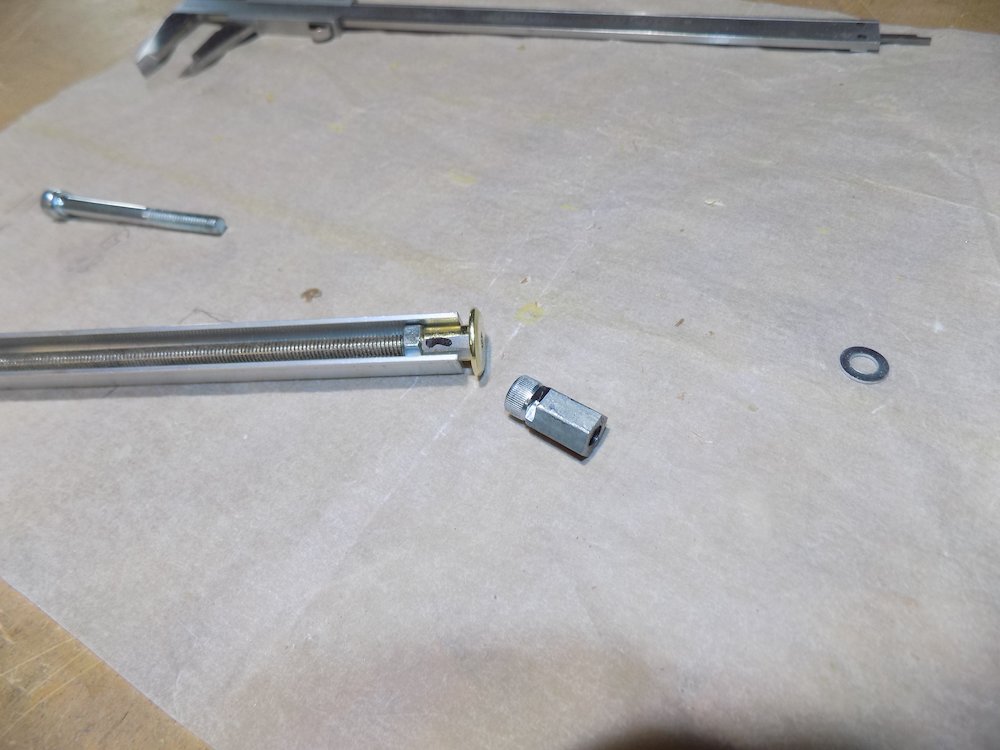

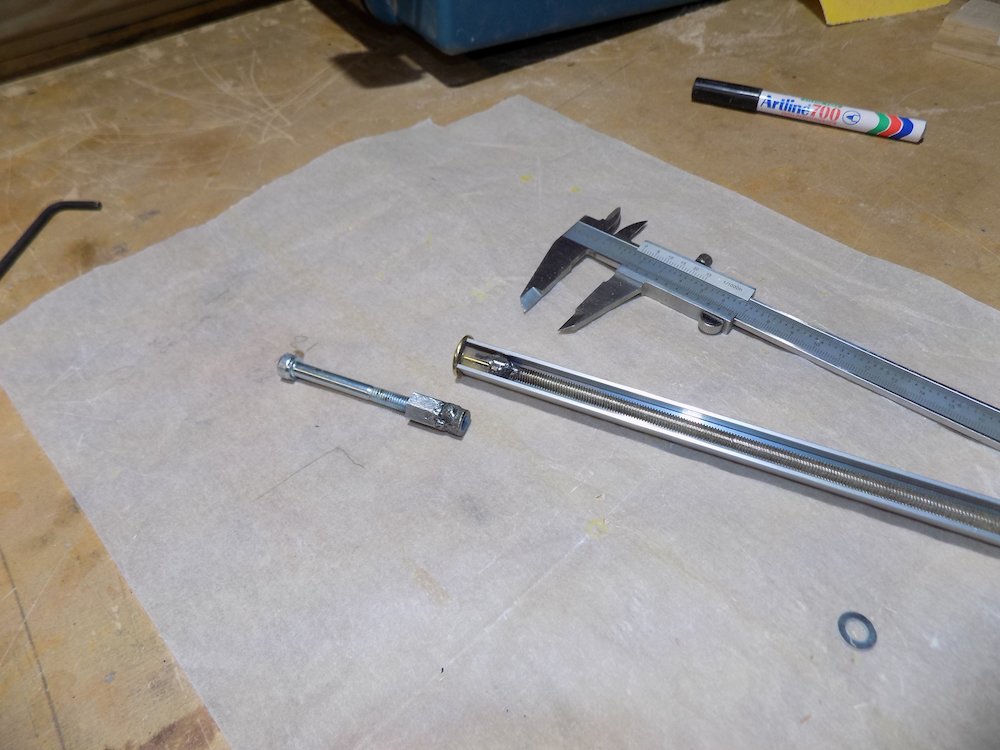

Truss rod (if not using a bought one)

NB: Regular acoustic guitar truss rod is too long for my GP model

there is not enough room for neck-tongue slot!!!

Therefore, can only use bought truss rods for bass

(as nothing available in parlor size)

Make Martin-style truss rods as per this video

https://www.youtube.com/watch?v=ysKRHdIaaEg

with some changes

use a furniture bolt "socket" nut instead of T-nut

12*12mm channel

M6 threads

3/16" / M5 washers (small diameter, they fit M6 threaded rod)

Lengths

Socket nut flange 2mm thick

coupler/barrel bolt 18mm

M6 hex head nut head depth 6mm

washer <1mm

nut 6mm

need 25mm clearance from body-fret (for neck tongue channel)

want to limit hex nut to ~15mm past nut, so truss rod cover can work

also want truss rod to end near zero-fret, where neck depth is deeper due to volute

Therefore, coupler/barrel bolt best cut down to 15mm.

Equation is therefore

take body-fret position (eg 345.1 for 24.5" scale, 14th body fret)

-25mm (neck-body clearance)

-2mm (socket nut flange)

-0.5mm (washer)

This is the aluminium channel length (318 in the above case)

Cut/grind coupler/barrel bolt to 15mm

Threaded rod should be this length +8mm (will be trimmed later) (326 in the above case)

Scale length |

Body fret |

Aluminium Channel |

Threaded rod |

24.75" |

13 |

304 |

312 |

24.75" |

14 |

321 |

329 |

25.5" |

13 |

314 |

322 |

25.5" |

14 |

332 |

340 |

34" |

14 |

451 |

459 |

Method

cut threaded rod & aluminium channel to length

cut/grind coupler/barrel bolt to 15mm

grind a 12x12mm square nut so that it friction fits in the middle of the U-channel, so tensioned threaded rod pushes against it for more bowing

fit regular M6 nut - the torque nut

fit furniture socket nut - the end nut

tighten them against each other

grind the sides of the torque nut square, with three facets flush with the furniture nut shaft

the rod, nut torque nut and end nut shaft should fit snug into the aluminium channel

weld the torque nut to the rod, then re-grind so it's square again

cut socket bolt, leaving about 7mm of free coupler thread

fit socket bolt to coupler

cut notch into coupler, up against socket bolt head

put a bead of weld in the notch to join the two together

grind the weld pretty

temporarily insert a long bolt into the coupler/end-nut

grind off the coupler facets manually, then put temporary bolt into hand drill, and hold it against grinder while spinning, to form a cylinder/bullet shape.

Finally use drill press as a "lathe" with sandpaper to polish it.

grind off the tops of the threads above the inserted square nut if required, so nothing extends past top of U-channel

U-channel

cut 3mm slots 17mm from each end (into the "top" of the U)

scribe a line 10mm from the U-bottom (2mm to be removed)

grind/cut/file/sand between the notches, so the U is 10mm high (notches now mark "flaps")

insert threaded rod one end

bend over the flaps at each end (vice)

grind off the portions of end-nut flange that protrude, leaving a squared end

NB: important

the threaded rod is only approxomately the length we need

if it is left too long, the truss rod adjustment nut will bottom out

remember (and check) that our adjustment nut has about 8mm of usable thread

thread a dummy nut, cut rod to exact size, remove nut so thread is useable

washer, wax/oil

spray with water dispersant

assemble & test

when adequately oiled, seal open side of channel with masking tape, and trim so channel sides are not covered

Truss rod components |

Truss rod preparation |

Truss rod welds |

Truss rod progress |

Truss rod ready for assembly |

Finished truss rod (not yet sealed with masking tape) |

Neck, headstock & heel

Cutting necks

Headstock scarf angle ~14deg = 19 rise over 75 run, slope = 0.248, angle = 14.2, hypotenuse = 77.4

The table below takes into account...

kerf losses (in combination with 14-degree angle)

heastock veneer

heastock section initially thicker to leave enough "meat" for the volute

Stock width: 65mm

Scarf joint table

"Scarf cut start" measured from heel-end, scarf cut will end approx 75mm further towards nut/headstock.

Scale length |

Body fret |

Stock length |

(12-string) |

Scarf cut start |

24.75" |

13 |

556 |

596 |

336 |

24.75" |

14 |

573 |

613 |

353 |

25.5" |

12 |

548 |

588 |

328 |

25.5" |

13 |

566 |

606 |

346 |

25.5" |

14 |

583 |

623 |

363 |

34" |

13 |

680 |

460 |

|

34" |

14 |

703 |

483 |

Heel pieces

Cut from same piece as neck, and adjacent to body-end of neck stock

Bass: |

130 at neck |

6 pieces (7*19=133) |

GP: |

99 at neck |

5 pieces (6*19=114*) |

Parlour: |

94 at neck |

4 pieces (5*19=95) |

Rough lengths: 125/95/90, 65, 55, 50, 45, 40

Cut heel and neck/headstock pieces, labelling each piece so that stacking the heel pieces can be done so that exposed end-grain aligns

Use well-rested quarter-sawn 65*19

Label so that any bow is *upward*, we don't want any back-bow baked into the neck

(fretboard will tend to produce more backbow, and we want to let the truss rod take care of it).

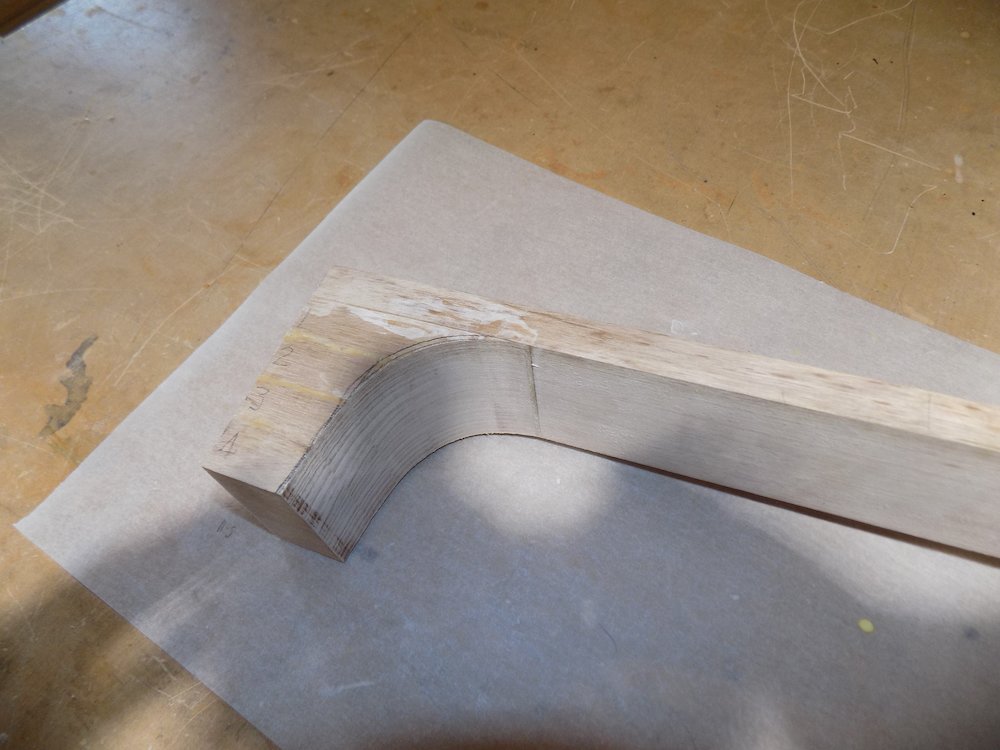

Cut scarf joint using jig on table saw

Aim for kerf to be evenly spaced around scribed hypotenuse line

Clean up wedge-ends by stacking so that hypotenuses align and sanding

NB: do this before drum-sanding the neck piece.

Get rid of any uneven saw grooves, blade-burn, and make sure each wedge-edge is straight and square

Scarf joint jig |

After cutting scarf joint |

Mill neck stock down to 16.5mm

But not the headstock piece, which we need to be thicker, so that it can "slide down the fretboard" by about 12mm, to give "meat" for volute

Mill the "shallow wedge angle" side, not the sharp one (which would shorten the piece)

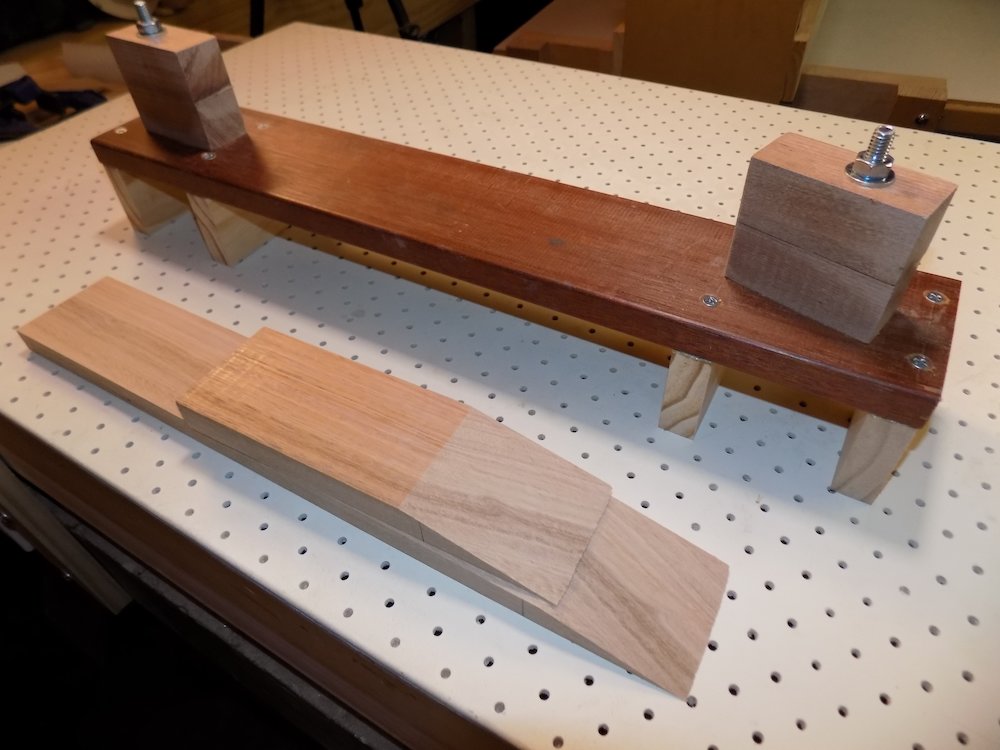

Align scarf joint using scarf joint clamping jig

This will prevent two problems

It stops the two wedge pieces from being pushed apart when clamped

If keeps the neck and headstock piece co-linear, ie prevents rotation

Glue up & clamp

Cleaning scarf joint faces |

Gluing scarf joint (old method) |

Scarf joint clamping jig |

Gluing scarf joint with jig |

Gluing reinforcing spline |

Gluing heel pieces, note alignment hole jig |

If headstock piece is not perfectly aligned with neck piece

(This was more a problem before using the clamping jig)

After gluing, mark a true centreline along the headstock, taking account of any rotation if the headstock piece was not perfectly aligned with the neck piece.

Use masking tape to shim sides of the headstock (or trim using table saw), so that they are parallel to this line

This is necessary as the headstock sides run along the router fench when cutting reinforcing spline channel.

Any headstock non-alignment may also affect cutting the truss rod channel.

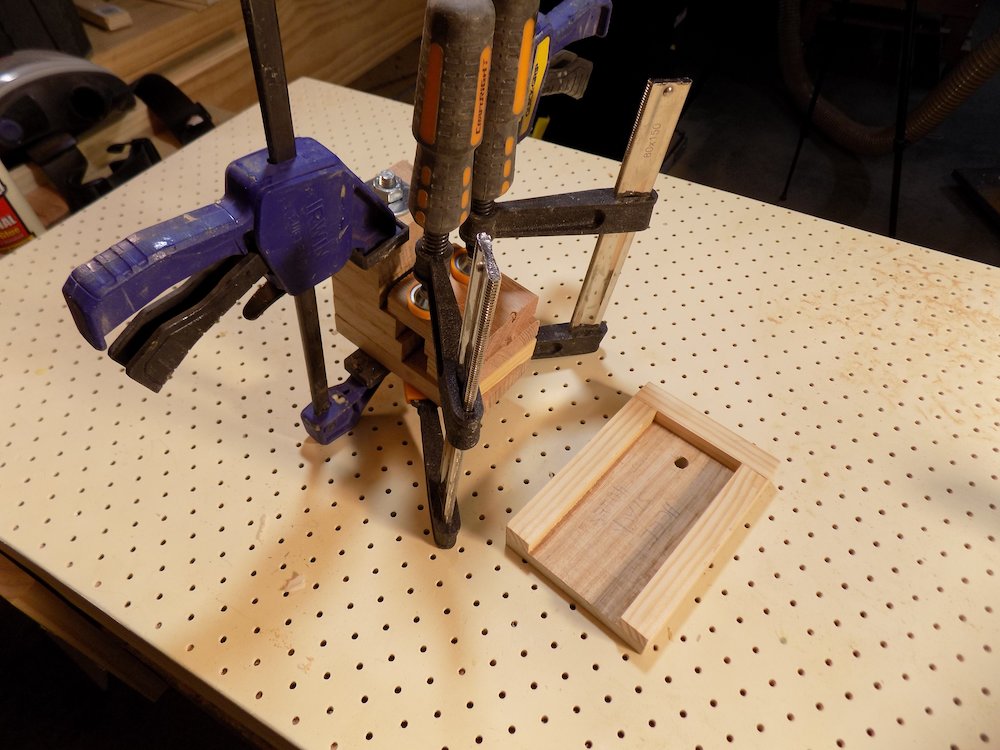

Use the heel alignment hole jig to drill 9.5mm holes in the heel pieces, then use a bolt when gluing them up

It will help the pieces stay aligned, and not slide when clamped

It will also assist with clamping (although additional clamps are still required)

Glue up heel pieces, making sure the grain lines up, but don't attach heel to neck yet

Clean up the upper face and sides of the headstock, perfectly flat, straight & square

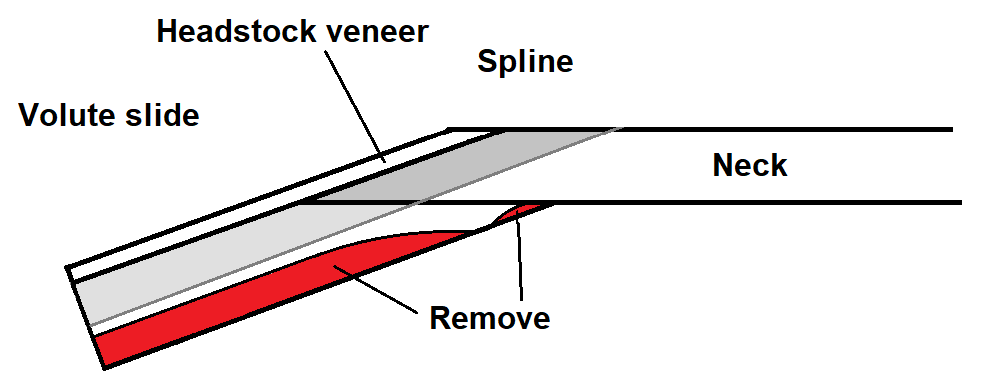

Reinforcing spline

Cut a channel along headstock, 8mm deep, about 18mm wide,

"bevelling off" into the neck (see diagram below)

use router table

channel should be aligned with neck (if any rotation in scarf joint)

always feed the piece right-to-left to avoid router pulling it away from fence

Scarf joint/volute diagram |

Mill and glue in spline, then level with sander, sandpaper etc.

Cut truss rod channel (12mm wide, 10mm deep) using router table

NB: do this before attaching headstock wings!

Headstock wings

Before attaching headstock wings

Rip headstock piece to 50mm wide (balanced around centre)

This will place the two heastock wing join lines "inside" the headstock, avoiding them appearing along the headstock sides (where the angle is acute, making them more obvious)

It does however make for a lot of tricky re-jointering...

Rip some 19mm stock, cut to headstock length-20mm:

6-String,Bass |

185mm |

12-String |

220mm |

Don't make them any wider than they need to be, thinner = more flex = more forgiving of imperfectly-jointered surfaces.

(Trim width to about 20mm or less, keep offcuts for side braces later?)

Rough-up the outer (dressed) sides (or clean up the ripped faces), and glue to headstock,

starting around 20mm from top neck-headstock vertex.

Make sure TOP faces are aligned (wings will be 3mm thinner than headstock, due to padding)

Narrowed-down headstock |

Gluing headstock wings |

Trim headstock ends square - NB: square to NECK, if scarf joint rotated a bit!

Thinning headstock, also forming volute curve

Rewmove dust shroud from drum sander

Slide headstock under sander drum, find end-position to leave volute "end" curve

- make a mark on the neck, 27mm from the inside scarf joint line (don't press too hard, pencil lines can dig into the neck)

- using a square, position this mark under the "start" of the drum

On the sander outlet end, clamp a stop piece at the position of the (squared) headstock end

Jack up drum sander dust shroud with ~32mm offcuts (clamp them for security)

Thickness headstock to <12mm (depending on the headstock veneer), pushing the headstock under the drum, against the stop piece, then out again

Turn the neck around, move the stop piece, and give the lightest dressing to the underside,

- just "kissing" the scarf joint

Setting up to thin down headstock |

Heel stack glued and squared up |

Headstock top after thinning |

Underneath showing start of volute |

Headstock veneer

Resaw & mill Blackwood and Celery-top Pine to <2.5mm, laminate

Show layer is Blackwood, the pine is to provide a contrast stripe around the outside

Aligning the pine layer cross-ply may strengthen the headstock wing joints, however it also causes three issues:

it may render the piece curved, causing problens when thinning in the drum sander

when sanding the wedge, the bulk of the work must be done after gluing it to the headstock, as the lower layer has edge-aligned grain

when trimming the sides of thinning the neck, pull out is an issue as part of the top of the neck has sideways grain

therefore, if doing it, it is essential to have longitudinal grain at the neck-end

one solution would be to have a piecewise transverse section in the middle (where it won't be seen), with longitudinal grain all around the outside

Recommendation: don't do it

If the result has some curvature, moisten, heat and clamp to remove it - this can cause uneven thinning in the drum sander

Pantograph router, avoiding disaster

clamp pantograph to upper right corner of router table

use wrapped stylus, so no play in template channels

clamp work-holder jig "underneath" that, perfectly square

clamp template 200mm from bottom left, with piece of 19mm stock for stylus "rest spot"

template should be pretty square to table

see image below

put mill bit in Dremel as far in as it goes

make sure the chuck is tight!!!

make sure workpiece has headstock outline, logo position and most importantly, centre line marked

draw cross-line 40mm under the top wave-motif line - that will be base of "M"

soft-clamp the workpiece in the work-holder jig

hover stylus above M-middle-bottom, move workpiece so mill bit is on crossline-centerline intersection

make sure *centerline* of workpiece is square to holder jig (and therefore, table top), screw down wingnut clamps

rout the inlay, "hovering" the stylus at first, then all the way in

make sure to go back-and-forth on all three M-feet.

Setting up pantograph |

Routing headstock logo |

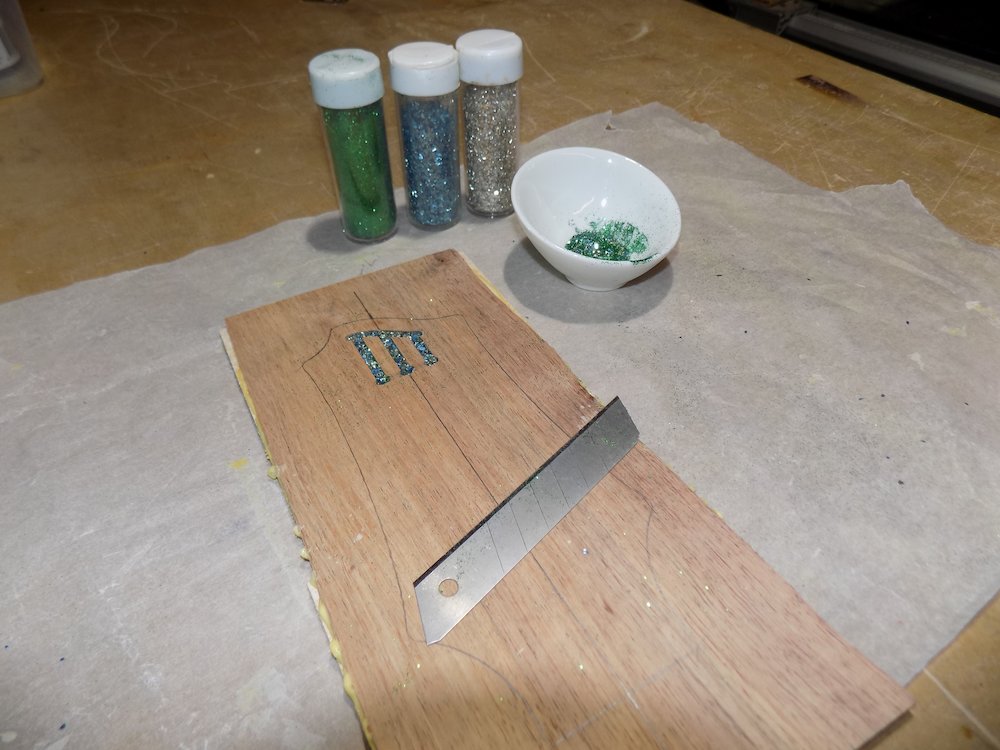

Mix some clear glass sparkle, turquoise glass sparkle and fine green glitter in a mini bowl

Fill the routed channels with glitter mix, to just under the top

- should be able to scrape an edger over without dislodging any

Apply a few drops of low-viscosity CA glue to partially fix the glitter in place

Mix a capful each of epoxy resin and hardener in a plastic cup (or cut off plastic bottle, whatever)

Drizzle the resin in careful not to drag the glitter around (CA glue should reduce this risk)

- make sure it covers each edge

Butane flame or heat gun to de-bubble

heat gun underneath to encourage resin to ooze down into channel

more butane flame to get rid of additional bubbles

Logo channel filled with glitter |

Logo channel filled with resin |

Carefully drum sand the veneer, first to reveal clean filled channels

then (front & back) to get down to 4mm.

If drum sanding pulled out any pieces of glitter

fill with CA glue (may require more than one application) then level with fine sandpaper

NB: do this now, and keep doing it until the surface is perfectly smooth. French Polishing is not the time to discover this was not done adequately!

Reestablish the centreline, using the centre pillar of the "M"

Retrace the headstock shape (onto the veneer) from the template, aligning with the centreline

Important: find the centreline at the far end of the headstock

Beware: if scarf joint is not perfectly square, more care is needed to find correct centreline

Transfer line so it is the same front and back

NB: in the following steps, 16mm is assumed to be the run of a 14-degree wedge of 4mm thick veneer

if the veneer is thicker or thinner, adjust to match

Trace two more lines onto the headstock veneer:

transverse line for the back of the nut,

and a parallel line 16mm forward (towards neck/body) of that

cut along this line

Mark a line on the headstock 16mm back from the scarf joint - this will be the back of the nut.

Logo sanded level |

Headstock veneer marked up |

Plan for truss rod adjustment nut to extend 14mm further past the end of the nut

The aim is for the end of the truss rod to be underneath the thickest part of the volute

Drill a 9mm hole in the veneer 20mm past the end of the nut (4mm past planned end of truss rod nut)

Cut a slot up to the hole on the bandsaw

With the bandsaw, trim away some of the veneer waste around the nut-to-wings flare

With the belt sander, cut off about 80% of the "upward sloping" edge of the veneer,

making a bevel, coplanar with the top of the neck.

Headstock preparation |

Headstock veneer slot and bevel |

Glue veneer to headstock aligning previously drawn centrelines

two small nails can be used to prevent slippage while clamping

use cauls to even out pressure since the veneer is thin

Finish veneer bevel with sandpaper and/or scraper, making a perfectly flat and flush transition to neck

Finish truss rod adjustment nut slot with rat-tail file, to allow hex key access

The slot will coplanar with the neck, bevel "up and out" of the headstock

Now is a good time to check for any neck-bow - remove by sanding and/or clamping

Gluing headstock veneer |

Neck with headstock veneer attached |

Continuing the neck

If pursuing bolt-on neck experiment

Mark body-fret line on neck

Mark neck-end of truss rod (notes immediately below)

Using router, widen & deepen truss rod channel at heel end to accept fingerboard support "prongs"

13mm deep, 37mm wide, extend to end of truss rod

Wood will be 16mm thick, that will leave 3mm at bottom of neck piece

Don't bother squaring them off, fitting the fingerboard support needs to be done later

Position truss rod so the end of the adjustment hex-nut extends 14mm past the back of the nut

Note that this corresponds to the aluminium section lines up with the fingerboard, and ends at the start of the nut.

We want the truss rod adjustment hex barrel to "just" protude up through the headstock veneer,

while the end of the truss needs to be above the extra thickness provided by the volute

The truss rod will have two deeper sections at each end (where the flaps are folded)

Use a chisel to carefully deepen the corresponding sections of the channel

Deepened channel at body end |

Deepened channel at nut end |

If not done yet, put some masking tape over the open channel of the truss rod, trim sides flush

Mix some Araldite, spread some on the sides only of the truss rod channels

glue truss rod in place, if slightly low in the channel that's ok (not high)

Truss rod sealed with masking tape |

Gluing the truss rod |

If the truss rod is low in the channel

Rip 12mm lengths of very thin timber, glue over truss rod

This is most important in the middle, where it will push up against the fingerboard when tensioned

Scrape/sand everything flush

Using the headstock template, clearly mark & square the position of the *back* of the nut

If all has gone well, this should be *just* inside the newly-sanded/exposed neck-headstock break

Mark a (squared) line 6mm down-neck from this - this is the fretboard/nut boundary.

Now we can mark the body fret line

25.5"/14th-fret |

359 |

24.75"/14th-fret |

348.6 |

24.5"/14th-fret |

345.1 |

24"/12th-fret |

305 |

34"/14th-fret(bass) |

479 |

Now we can plan neck width profile

Mark centreline at body-fret, then *centred* body-fret neck width

6-string: |

56 at 14th fret |

12-string: |

59 at 12th fret |

Bass: |

58 at 14th fret |

Mark *centred* nut neck width

6-string: |

44 |

12-string: |

48 |

Bass: |

42 |

Rule in neck edge cut-lines

trace in headstock-neck transition lines (make them symmetric)

Take already-glued-together heel block stacks

If drawing a line on the underside of the neck, don't press too hard, pencil can dig in

Bottom of stack will be ~45mm

Bottom of heel will be 35mm

Glue & clamp, with about 5mm spare each end

Marked up neck |

Gluing the heel stack to neck |

Transfer neck edge cut lines (width lines) to the underside of neck

NB: heel block may not be square - use set-square

Transfer headstock outline to back of headstock:

Cannot cut headstock shape right way up due to headstock angle

This will be hard to get 100% accurate, when we cut it out (later) we'll leave plenty of space so that it can be finished on the belt sander with frequent checking of the front.

Heel curve cut and sanded |

Neck outlines drawn ready for cutting |

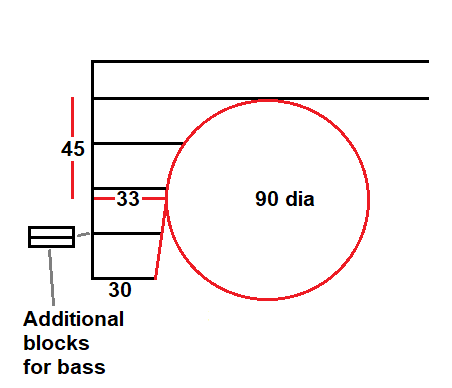

Use this diagram to rough-in heel curve.

Roughing in heel curve |

This is a very rough guide

Measure 45mm down from the underside of the neck piece

Measure 33mm in from the bodyline heel cut

Measure 30mm in from the bottom of the heel

Trace a quarter circle from that point to the underside of the neck piece

Extend the bottom part of the curve to 30mm in from the bottom of the heel

Rough the shape in on the bandsaw, then get closer on the belt sander

Cut the body-join line on the bandsaw using the mitre

Be careful that the heel block might not be quite square

Clamp neck to mitre, making sure that everything is square

Now we can cut the neck to width on the bandsaw, leaving about 1mm to sand down accurately

Start the process - shallow vertical lines along the heel - on the table saw

Then do the neck side lines, starting with those groove-cuts

Neck and headstock rough cut, bottom |

Neck and headstock rough cut, top |

Carving the neck shape - facet method, assume 16-17mm neck thickness,

Aiming for a nice "C" shape

first facets 15mm into the back, 10mm up the sides of the neck, flaring to 15mm at the heel

This will leave 6mm of vertical timber each side of the top of the neck

Second facets 4+4 (moving out from fretboard) and 6+6 (along the inside towards middle) - two of each

This will leave 2mm of vertical timber each side

Note that this seems "too much". but our neck is wider than it will eventually be...!

Neck facets |

"flare" facets outward around volute and inward at the headstock - don't overthink it, it's pretty easy.

Smooth remaining facets, sand out rasp lines

Use Shinto saw rasp for straight sections, curved rasp for heel curve

Remove some of the scratches with a regular wood file

First facet lines |

First facets cut |

Second set of facet lines |

Seconde set of facet cuts |

After cutting the three sets of facets, round everything over with a wood file

Coarse sandpaper to move closer to finished surface

Around this time, re-transfer & cut headstock shape (leaving 2mm extra) using bandsaw & belt sander.

Neck shaped and smoothed: heel end |

Neck shaped and smoothed: headstock end |

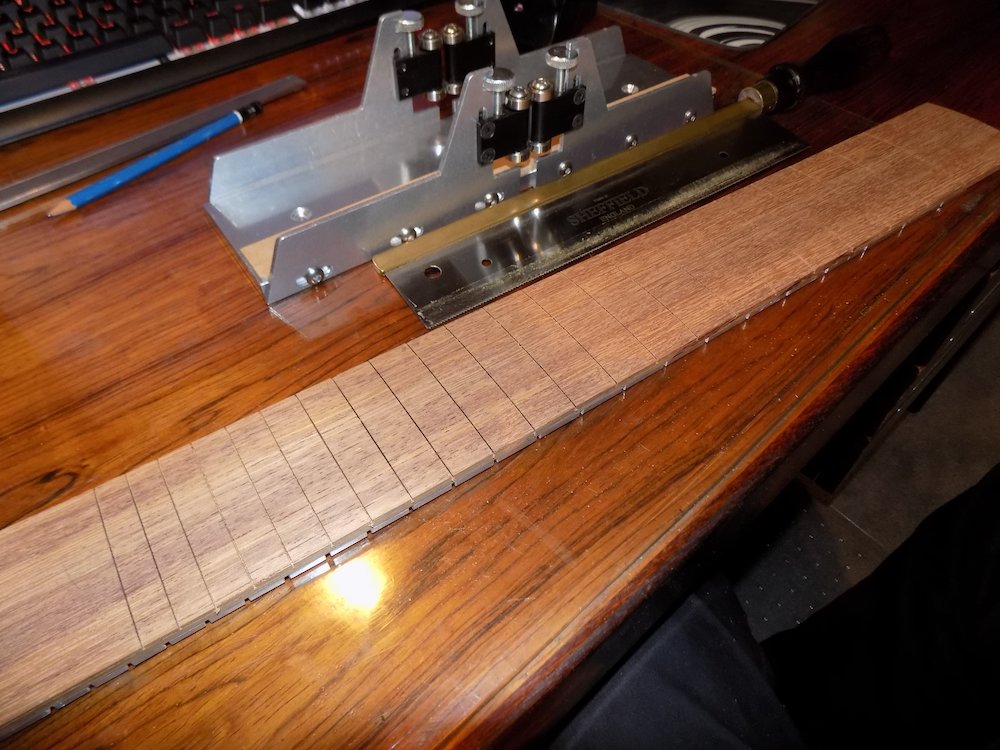

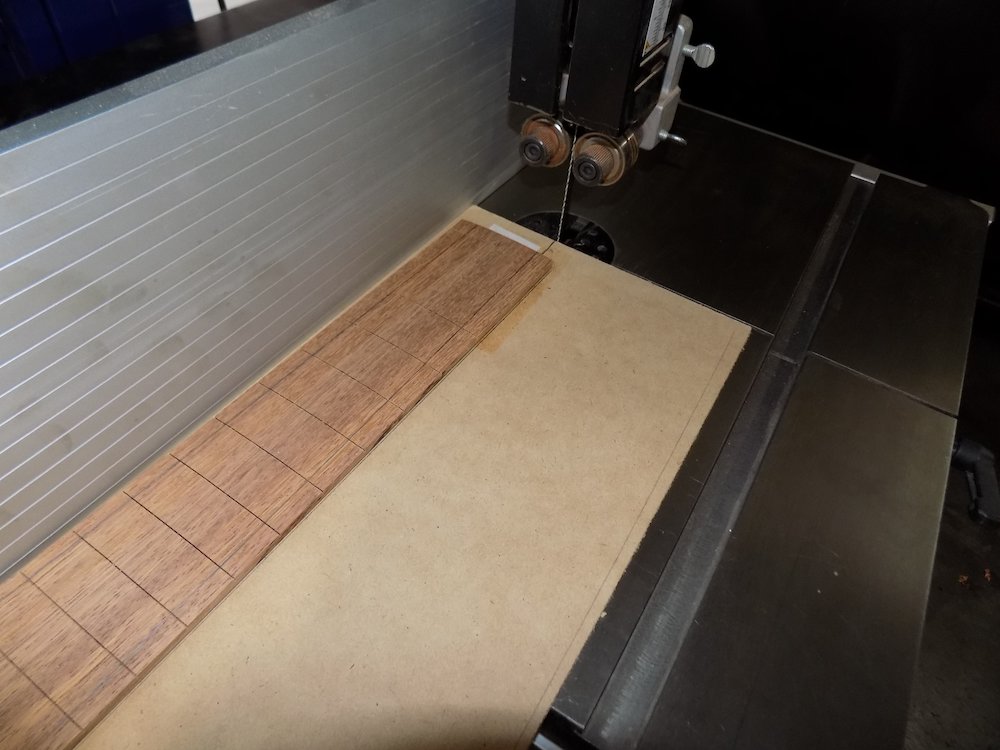

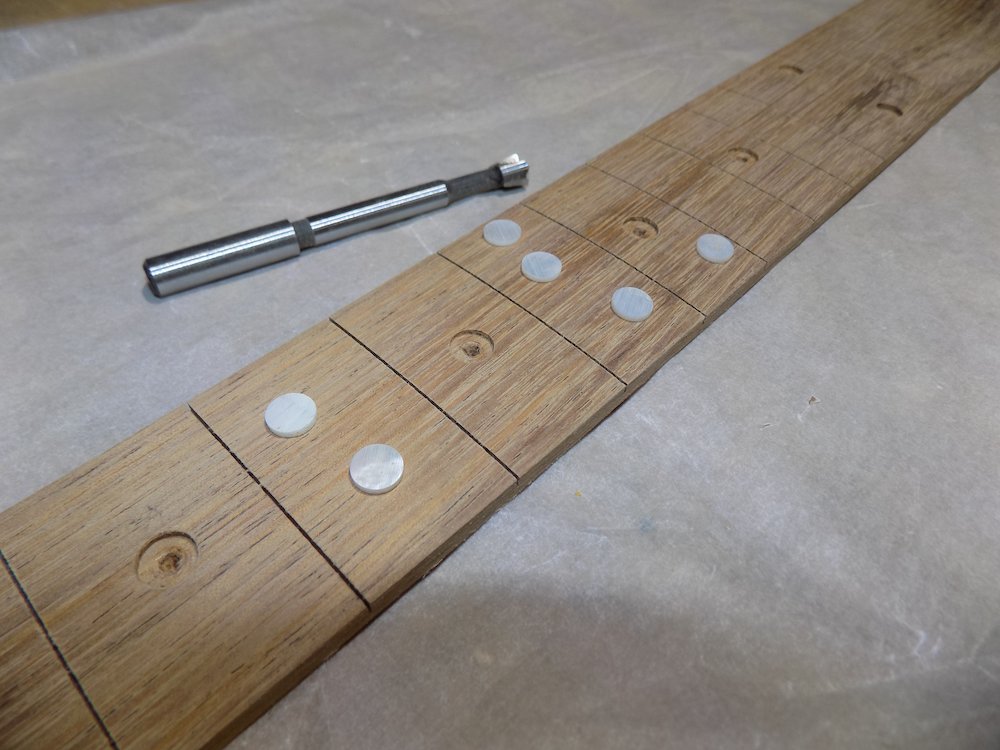

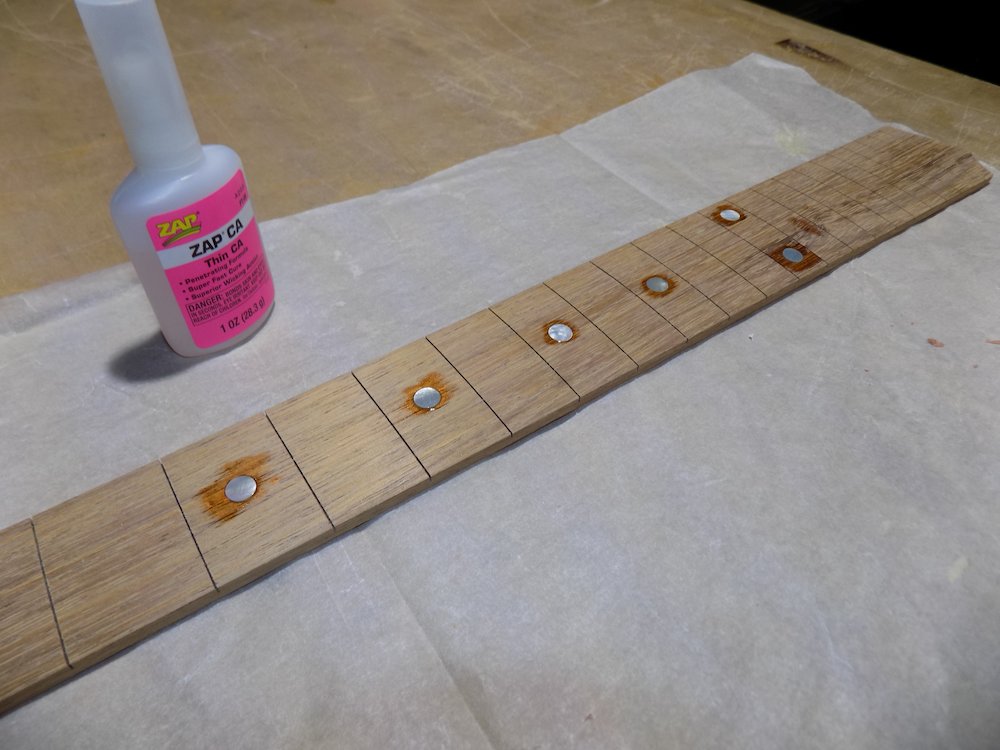

Fingerboard

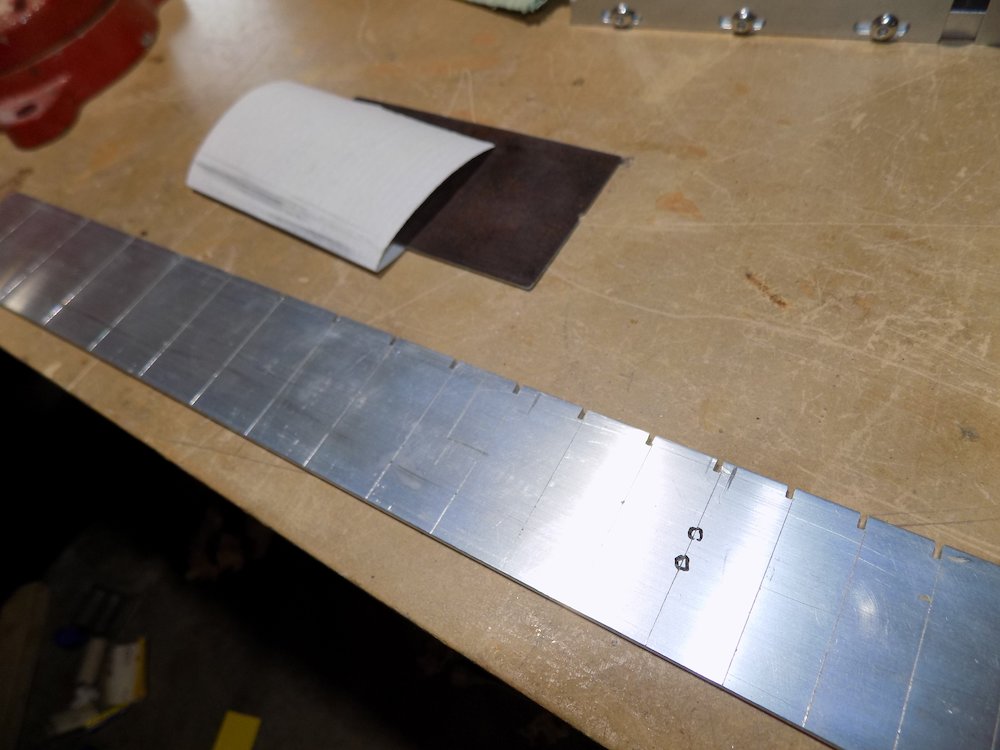

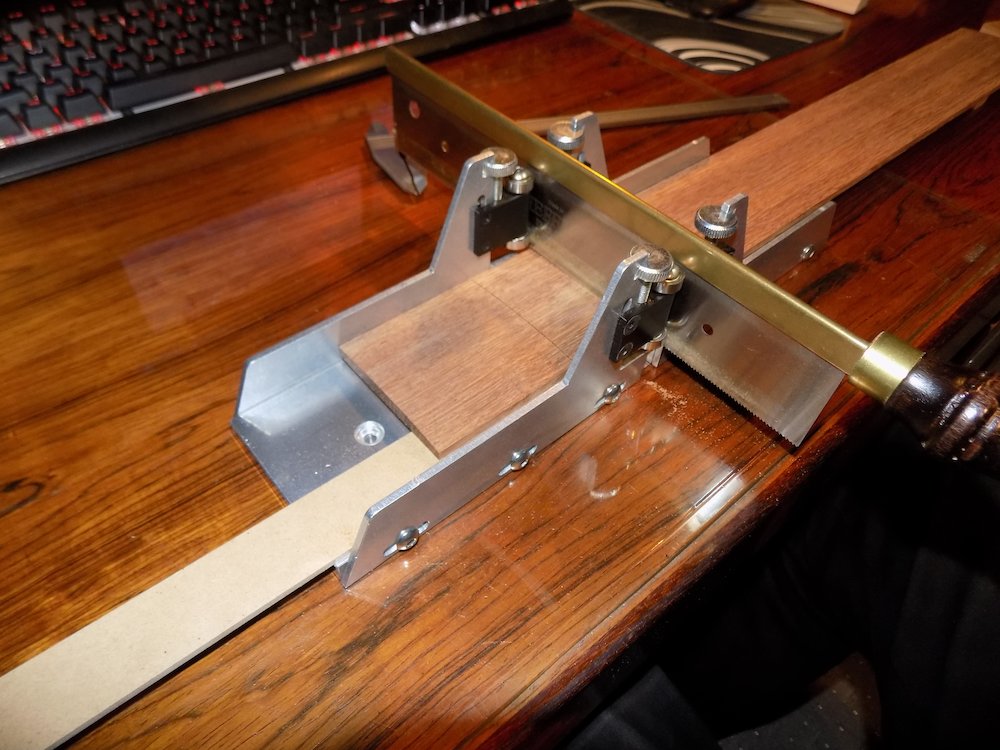

Mill Merbau / Jarrah / Spotted Gum to 6.5mm, 66mm wide

Rough cut lengths

25.5" scale |

510 |

24.75" scale |

495 |

34" scale (bass) |

650 |

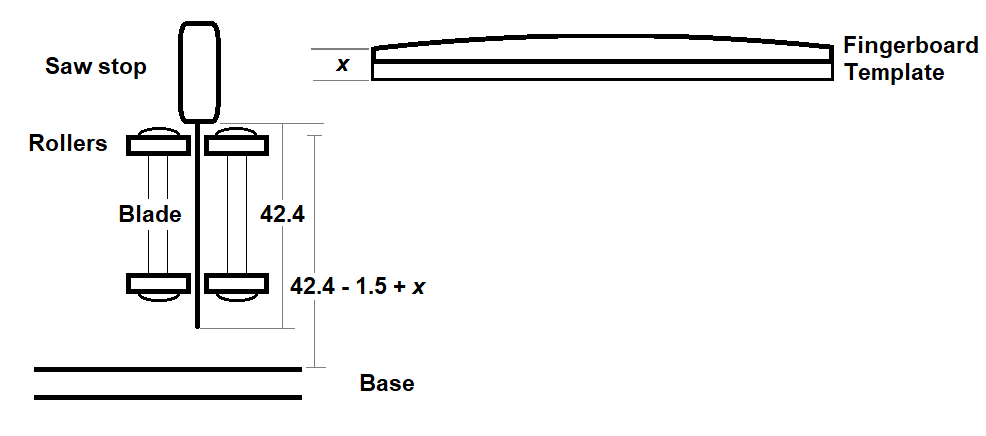

Rough in radius using drum-sander sloping jig

Draw scribble lines all over the surfsace

Make two sets of passes through the drum sander, rotating the work lengthwise

We want the two bevels, each being about a third of the width wide

The pencil scribbles allow the depth of cut to be judged accurately

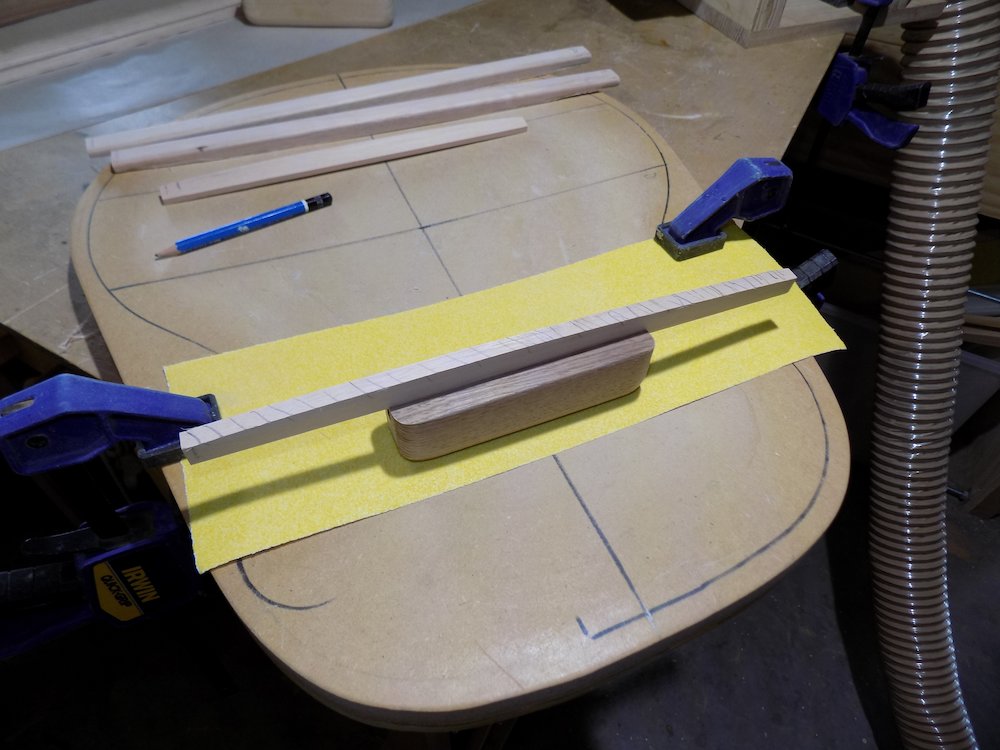

Finish radius with 11" radius sanding block

Fingerboard bevels cut using slanted cradle jig |

Fingerboard profile using radiused sanding block |

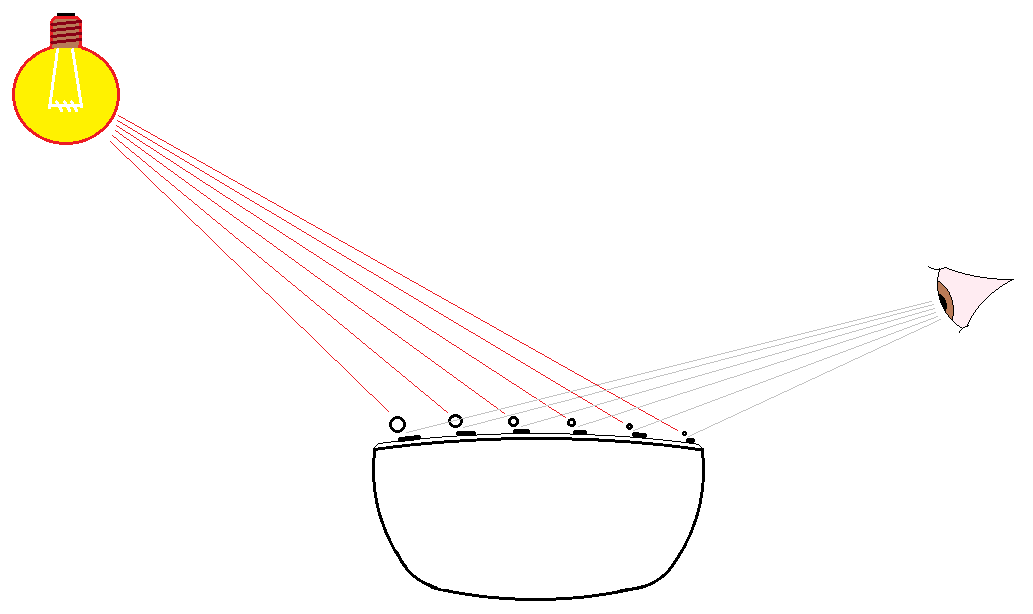

Sides philosophy

Since kiln-dried timber is more readily available (and therefore, more choices with respect to grain, quarter-sawn, etc), we have chosen to go with it.

Kiln-dried timber is however much harder to steam-bend, and therefore needs to be milled to ~2mm

That's extremely thin at the best of time, but our steam bending process (with Tasmanian Blackwood, at least) of that thickness leades to lateral waviness

We therefore use a laminating process, to get adequate robustness, and allow sanding out the waves.

Originally I used plain old pine for the inner layer, but I've switched to Macrocarpa

Waviness

Steam bending Tasmanian Blackwood, especially a 2mm thin layer for lamination, introduces waviness across the grain.

Usually 2mm is enough for this to be sanded out before cutting the binding channels.

However, if the bindings turn out to be too shallow, or other unexpected situations, we can end up sanding through the outer layer.

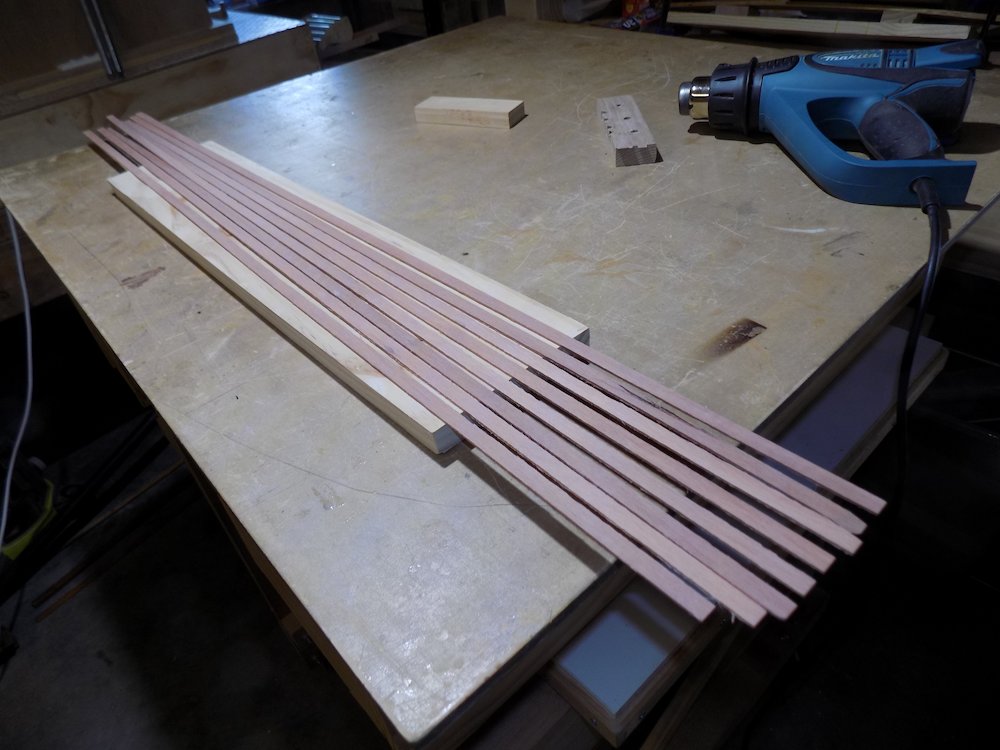

Milling sides stock

Mill to: 2mm (two sheets per side, to laminate to 4mm)

Bass |

155 x 950 |

GP |

120 x 850 |

Parlour |

113 x 800++ |

Those measurements assume near-perfect placement in the bender, allow a little more if unsure

Resawn side stock |

Side stock milled to 2mm |

Side bending

Assume

mould is in Fox bender with lower bout to the left

if there is a colour gradient across the side stock, we prefer darker toward guitar back

Then

Non-cutaway side: Darker side is to the rear

Cutaway side: Darker side is to the front

NB: New aluminium foil each time! Four layers on wide pieces (bass)

Aluiminium foil stops steam from escaping, and protects against iron contamination (from shim-stock in bender, and filings from when we made the truss rod). Iron reacts with hot, steamy timber and stains it irretrievably black.

Laminate each pair backwards, so blackwood "show" side is protected by what will be the inner layer

Shim stock process

Steel shim stock protects the timber by evening out bending stresses and heat

Under the wood: one layer of aluminium flashing, sprayed with black engine enamel, to better absorb heat lamp energy.

Aluminium is also bendier, less springy, plasing less stress on the bent sides when removing from mould

Following that: one layer of 1/100th" steel shim stock

Over the wood: two layers of steel shim stock, but the outer one only over the waist and cutaway area

Heat top shims with heat gun while operating the Fox bender.

Order of operation:

Tighten waist press screw to keep mould and work steady

Make sure work is parallel with sides of mould

Measure so that the work piece will extend about 40mm past the end of the bottom of the mould's lower bout

For all the following steps, play the heat gun over the exposed top shim stock, to help heat the workpiece

Bend down the lower bout, keep it in place with the spring clamp

Bend down the upper bout, keep it in place with spring clamp and/or cutaway press screw

Slowly tighten waist press screw

If making cutaway sides, even more slowly tighten cutaway press screw

Leave work in the bender with lamps on for about 5 minutes, then let them cool down for about 45 minutes.

After removing them, allow each piece to dry thoroughly before next steps

Consider clamping them in the laminating mould to dry, to reduce springback

The mould used to bend the sides |

A Fox-style side steam bender |

Pre-heating sides |

Steam bending non-cutaway sides |

Steam bending cutaway sides |

Bent sides after allowing to dry |

Also

Do the bindings while the Fox bender is set up

Two-layer, same colour

Milled hardwood 9.5x1.7mm - make sure all edges are clean

Update: intend to experiment with less-deep bindings to reduce tilt-gap problem (see bindings step, below)

n-layer with accent colour on the inside

See bindings step, below

Make sure grain is straight along the bend dimension

4x each side

Bindings ripped and milled |

Bindings bent using same process as sides |

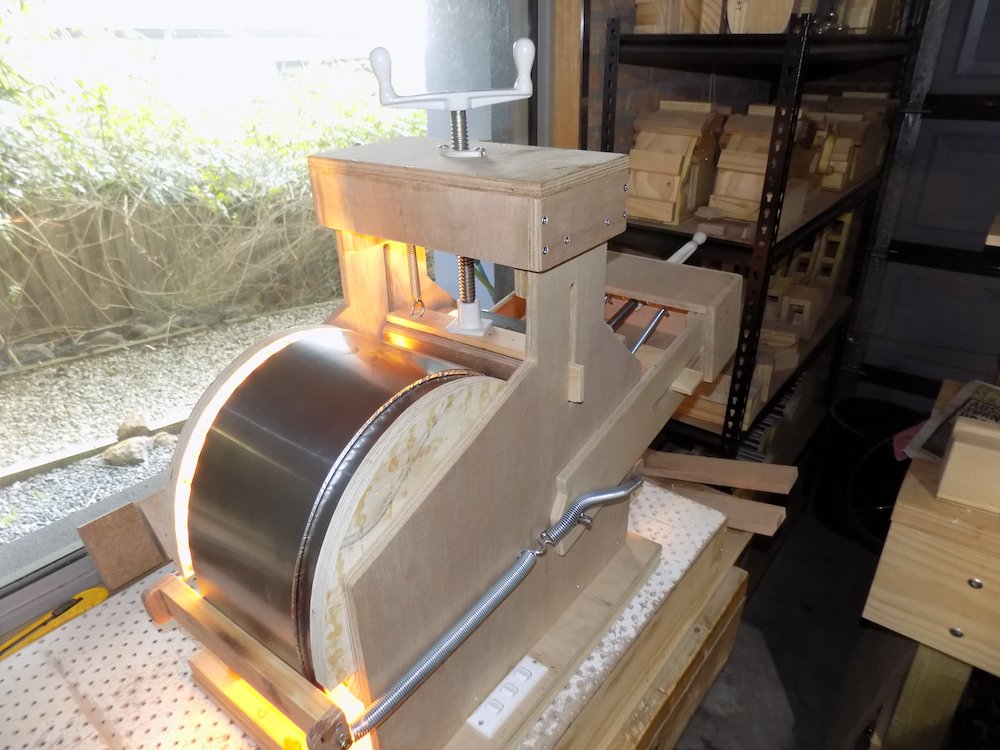

Side Lamination

Place side pairs in laminating moulds, and trim off excess that otherwide prevent moulds from standing on workbench

Laminate pairs in laminating moulds

Radical decision: use Polyurethane glue!

fills gaps due to inadequate clamping

(Aliphatic glues, ie Titebond, produce voids, even with the best clamping)

Procedure

Put masking along sides of both mould and clamping caul, extending sideways

Apply glue sparingly!!!

It is critically important that the sides are perfectly aligned with the mould, clamping tight from one end to the other can cause this to "creep in".

Loosely fit all clamps, check alignment, then tighen

Note that the masking tape may make this problem harder to see

Too much squeeze-out makes extraction from mould tricky (hence masking tape)

If any squeeze-out has gotten onto mould, remove from mould *approximately* after three hours (depending on weather/temperature),

while glue is soft enough to separate easily,

but inside the lamination, strong enough to hold

NB: if taking the sides out of the mould early, put the cutaway side back in afterwards, and reclamp

- tight - so that there won't be any spring-back due to soft glue (which then hardens, cementing the wrong shape!)

Gluing the sides for lamination, see laminating moulds to the rear |

Laminating non-cutaway sides |

Laminating cutaway sides |

Sides laminated |

Fitting sides to solera mould

finalise neck-width at body-fret, create shim between solera mould-halves so cutaway-edge-to-centre is half that

Do not skip this step - solera moulds are a little thin on the neck joineven better, glue permanent shims for the standard neck width, so that we only have to shim for 12-string (or 5-string, in the case of bass)

Model |

Neck width |

6-string |

56 |

12-string |

59 |

Bass |

58 |

Fitting sides into solera mould is tricky, follow these steps carefully

Manually estimate cutaway end, as it will not fit into mould until near-perfect

Cut outside that estimate, fit inside and see how much needs to be trimmed so cutaway curve matches solera as closely as possible

Again, cut slightly less than that, repeat until satisfactory

Fit both pieces inside their respective half of the solera mould

Mark how far the tail each end extends

Cut 5mm short of that line

Attempt to clamp the two halves of the solera mould together

The tail will be out by about 10mm, mark how much needs to come off each side

Cut slightly less than that off and reclamp

The neck end will be way out, measure the gap between the two neck-ends of the solera mould

Cut that much minus 5mm from the non-cutaway side

Reclamp, check if solera mould can clamp together tightly

Also check verticality of sides around perimeter

Keep cutting a little at a time until perfect

A misaligned centreline at the tail end is quite OK, it will be hidden by tail strip and access port cover

Depending on how secure the fit is, out-pressing turnbuckle clamps may be needed while cutting front and back profiles, and gluing access-port frame and neck block

Sides trimmed and fitted in the solera |

An assortment of solera turnbuckle clamps |

Trim top of sides to create soundboard edge

if sides are loose, consider gluing a temporary joiner piece to the place where the access port will be cut out

Spokeshave time

use laminated MDF reference flat surface

raise frame slightly and evenly

make sure every point along the sides are vertical (use set square)

slide a pencil around the inside perimeter, drawing a line

shave and plane to that line to get a perfectly flat top edge

edge can be checked with MDF reference surface

sticking sandpaper to MDF surface with double-sided sticky tape can zero in final flattening

NB: we only need it flat so we can measure the curved back profile points

the actual top profile will be adjusted to a more complex curve using a very shallow spherical sanding dish - later

Profiling sides: flat for the top, curved for the back |

Curved sanding sticks used in side profiling |

Trim bottom of sides to create curved back profile

Invert, mark dimensions for cuved back

Position |

Bass |

GP |

Parlour |

Tail |

max- 6 |

4 |

4 |

12% |

max- 2.5 |

1.5 |

1.75 |

25% |

max- 0.5 |

0.25 |

0.5 |

37% |

max- 0 |

0 |

0 |

50% |

max 1 |

1 |

0.5 |

62% |

max- 3 |

3 |

2 |

75% |

max- 6.5 |

6 |

5 |

87% |

max-11.5 |

10 |

8.5 |

Neck |

max- 18 |

15 |

13 |

With standard heights of Bass: 150, GP: 115 and Parlour: 108, that means

Position |

Bass |

GP |

Parlour |

Tail |

144 |

111 |

104 |

12% |

147.5 |

113.5 |

106.25 |

25% |

149.5 |

114.75 |

107.5 |

37% |

150 |

115 |

108 |

50% |

149 |

114 |

107.5 |

62% |

147 |

112 |

106 |

75% |

143.5 |

109 |

103 |

87% |

138.5 |

105 |

99.5 |

Neck |

132 |

100 |

95 |

Take care around cutaway - height *increases* towards centre!

two-dimensional curve

longitudinal curve governed by curved sanding stick

lateral curve much less than sanding stick curve,

lateral curve near cutaway with shorter, shallower sanding stick

This can be roughed in, and finessed later (after kerfed linings attached) with curved sanding sticks

If a well-shaped result is achieved while still too high, keep it - it is much easier to cut down the flat topside to the correct size

Turn work over to check "roll" of edges against flat surface

Avoid any "sharp" spots (tilt rather than roll), they will make fitting bindings more difficult

In paricular, the measurements above have a sharp spot in the middle that is intended to be rounded over

Back profile from neck end |

Back profile from tail end |

Gluing neck block

Mark the two angled bevels that need to be cut

One on bottom, to fit into curved back - flat OK at first

One at the side, to fit into cutaway - will need to be sanded concave

Use the narrow convex sanding block to match the shape of the inner cutaway

NB: neck width at body fret needs to be considered

need centre of tongue-channel to be 0.5*neck width from outside of cutaway face

(see table above)

NB: Double check that sides (especially around shoulder/cutaway) are square to the front. Gluing the neck block commits to the that alignment.

Glue and clamp

Neck block cut and contoured |

Gluing the neck block in place |

Bolt-on neck block glued (top) |

Bolt-on neck block glued (bottom) |

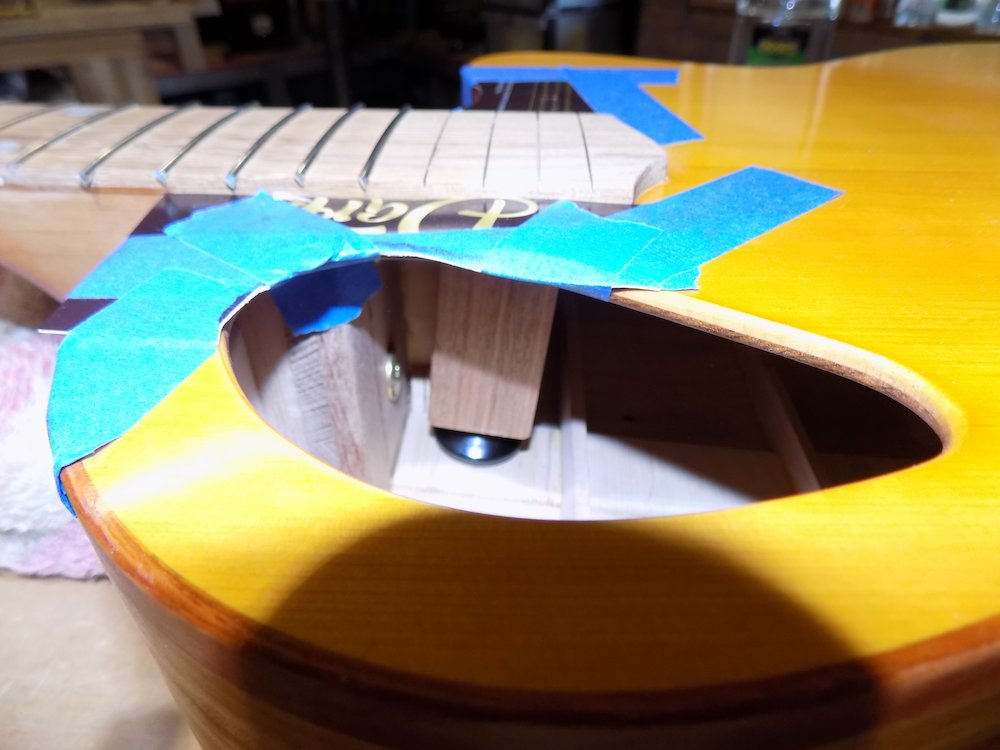

Gluing access port

Assemble all layers together (two sets not glued), cover screwed in place (for alignment)

NB: cover can't be in place if "temporary joiner piece" glued at seam

Position, centre vertically and horizontally, mark layers, trim leaving ~1mm top and bottom

Glue outer piece, so that the extra 1mm is evenly distributed top and bottom

clamp the outer ends with same convex clamping cauls used when laminating access port frame upright components

Don't bother sanding it flush yet, wait for the kerfed linings.

Mark true centre, top and bottom, tail and neck

Remove from mould!

(possible thanks to over-engineered sides and single access port frame layer)

Cut ~2mm deep slot (dado style on table saw), then cut and fit tail strip

(much harder to do later, after we cut the actual hole)

Also, end-tear-out is less of a problem now

(Surface tear out can be managed by decent blade and/or slow feed speed)

Centre over true centreline (might not be sides join-line)

Before finalising width, put back in solera to check alignment

Glue in, then trim and level

It is quite acceptable to cut the tail strip in two so that it just covers top and bottom, as the access port hole is about to be cut out

Using drill, hole-saw and router(flush bearing bit), remove material from hole

Drill and hole-saw: remove the bulk so the router does less work

Router: flush bearing bit to rout sides to line of access port outer layer

Remove any glue on access port sides first, so routed line is straight

Square out corners with rectangular file so cover fits through

a regular rectangular fire, while slower than some alternatives, is safer:

Make a notch in the rounded corner, then work it outward and downward until both edges are straight.

The end result if this step is that the cover should fit through (and sink into) the hole, so that it is flush with the inside (ie, to its final depth)

The steps involved include

Making sure the outide hole perimeter is straight, square and it true corners

Fitting the cover in as best as possible, then putting your head inside the guitar, looking in a light source, and noting tight spots

Drawing lines with a pencil to show when you are filing parallel to hole edges

At the very end of the process, it might be appropriate to sand the cover itself, particularly to adjust the angles the two ends

Trimming access port |

Channel for tail strip |

Gluing tail strip |

Routing access port hole |

Access port hole routed |

Access port hole squared out |

Fit inner layer (using partially completed cover to align)

Mark sanded/trimmed top & bottom line, trim

Holes drilled yet?

Glue and clamp inner layer,

fit cover (including bolts) to ensure the two layers align

note that some of the inner layer face does NOT require glue!!!

use frame-to-sides clamping caul with exact shallow curve at each side of the frame

remove cover immediately so it won't get stuck by glue squeeze out

Gluing inner layer of access port |

Door removed after using it to align the glue-up |

Problem of inner layer springback

Clamping outside solera mould may change tail curve

Access port cover curve may no longer match access port frame

Current procedure

After gluing in the middle layer, inspect:

The resulting curve of the sides+middle layer

The curve of the as-yet-not-glued-in inner layer

The curve of the cover

Take remedial actions as required:

Relax or tighten curvature of middle layer before gluing by wetting, heading, clamping

Relax or tighten curvature of cover (wet / heat gun, clamping)

Consdier whether the laminating moulds need to be remade/adjusted before laminating in the first place

Also, consider

just how different is the curve?

Will it still fit into the solera?

Remember cover will be bolted in place, inside solera when attaching back and soundboard

Will the difference in tail curve be noticeable when the guitar is complete?

Previous approach (not recommended, not shown in images)

rub some candle-wax around inside of cover

rub some candle-wax around non-glued surfaces of frame

leave cover in place while clamping

Finish access port

Prepare the following

outermost layer (actual show piece), ~1.7mm, curved

second-outermost layer, <2mm, also curved

some strips of border accent wood, ~12 x 2mm, straight

To create the outermost lamination

Carefully trim/sand second-outermost so that it fits into the hole,

OK if it doesn't quite go all the way in against the coverCut border strips with the top and bottom pieces full width and the uprights fitting between them

Cut the outer centre panel so that it fits between the border strips

Use sacrificial backing, as tear out affects the show face

Glue and clamp top and bottom strips and centre panel

The cover can act as a clamping mould for this step, since the top and bottom border strips are not pre-curved

When dry, excavate any squeeze out from the channel where the side border strips are to go

Glue and clamp the side border strips

sand the border strips flush(ish)

redo the fitting, as perimeter will have changed...

This almost final perimeter fit

trim to within ~0.5mm on table saw, cutting "inwards" to prevent tearout

sand top and bottom so that the piece fits

for each side, slide up, inspect gap - there will be some unevenness

sand out until each end slides up perfectly

check overall width, reduce and reprofile appropriate side-end as needed

Before proceeding, check that inner cover curve matches guitar

if it is too shallow, consider shimming the two side edges

if it is too deep, consider shaving down the two side edges

also consider wetting / heat gun / clamping to adjust curve

At this stage, it may turn out that the cover doesn't sink in as far as it should

This may lead to the outer layer being too proud, and requiring too much levelling

Especially if the two outer layers are too thick

Consider very gently sanding the outside of the cover, to thin it a little

Don't overdo it, glue squeeze out on the cover show face (panel, border) will require some levelling

Tack two thin nails through inner cover, poking outwards 2mm

Angle (relative to the curve) so they're parallel with each other (not flaring out)!

Fit inner cover

Press outer cover layer into place, impaling it against the two nails

Remove

Laminate outer layer, using nails as index for alignment

if at all possible, remove as much squeeze out, as sanding/scraping/chiselling it from a fit-critical edge is not much fun

Remove nails

Index pins (nails) to align outer layer of access port |

Fitting the access port outer layer |

Extend five holes (strap button in middle, four countersunk screw holes at corners)

Fit cover in place

Screw four corner bolts through holes (apply some candle-wax first)

Glue in place the two nut-strips we made when laminating access port layers

Best done with cover in place, but need to manage squeeze out

Rub some candle-wax around inner edges of cover

Apply glue to inner face of nut-strips (if possible, not the parts exposed at the edge)

Position nut-strips in place

Tighten four bolts so they engage nuts and extend inwards

Clamp (bolts are only pulling against nuts, nut-strips are just sitting over them)

Gluing the access port outer layer |

Preparing to glue the nut strips |

Gluing the nut strips |

Finished access port |

Hopefully end up with cover fitting, as well as the four bolts

Scrape and sand flush if any major level discrepancy (lots of further sanding to be done later)

Clearly mark centre lines on side frame

both ends, top and bottom, glue faces, inside, outside

I mean, it's so annoying when you have to keep working it out again...

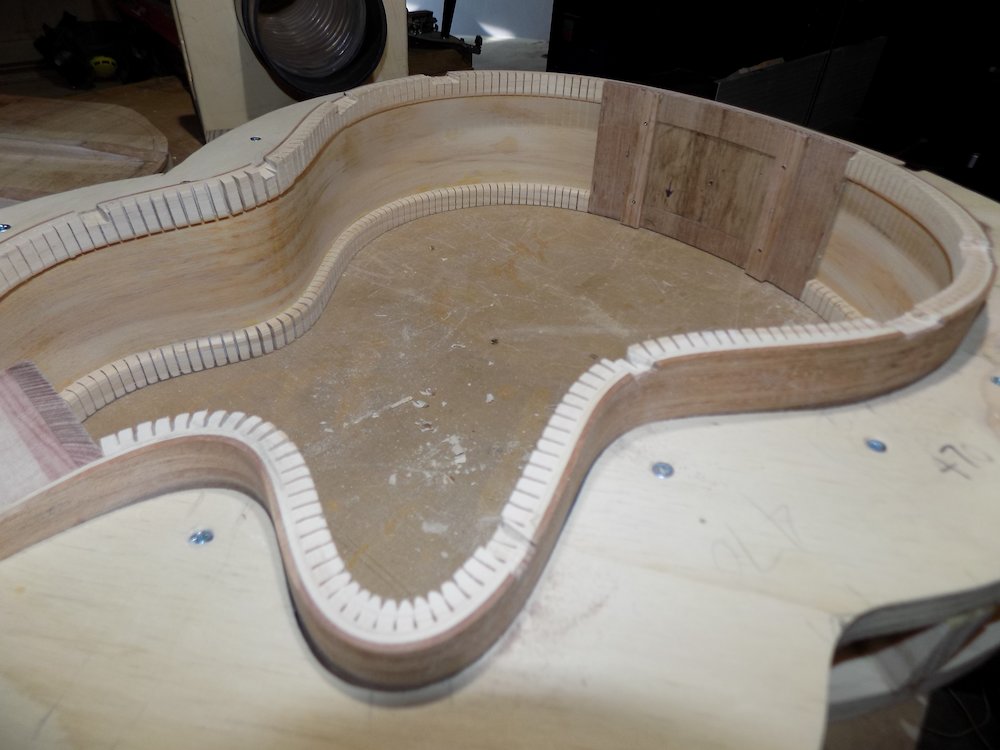

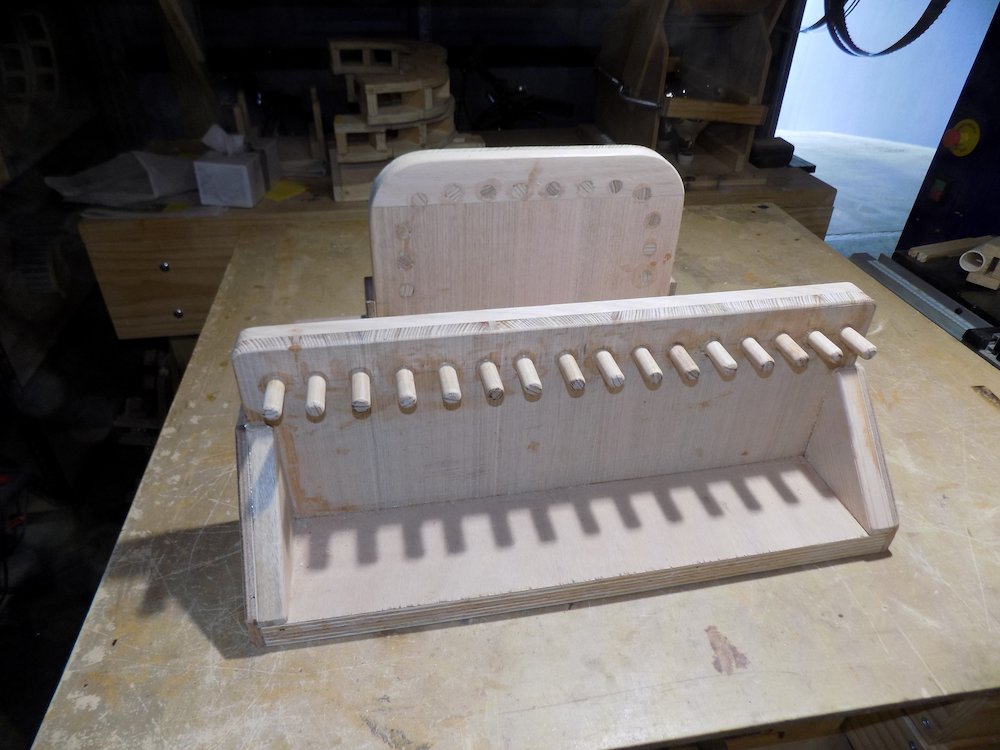

Kerfed lining

19mm stock, rip and mill to 7mm, the put a radius on one of the side edges

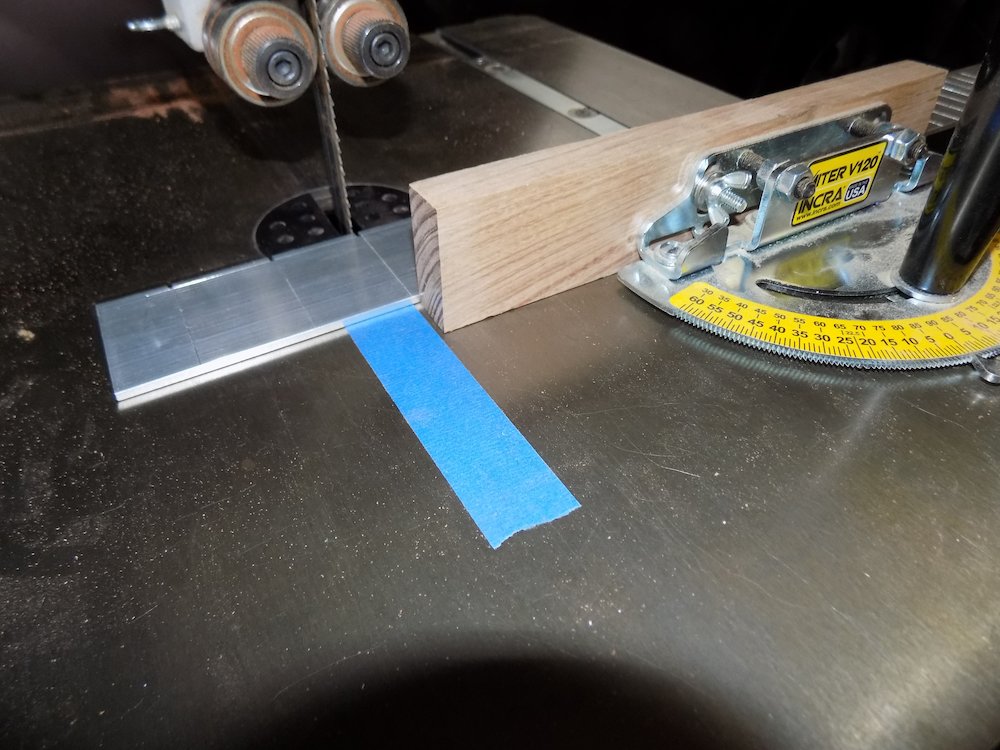

Bandsaw guide - slotted stop board,

use headless nail to get each cut "evenly" spaced lol

Also use bandsaw table extender

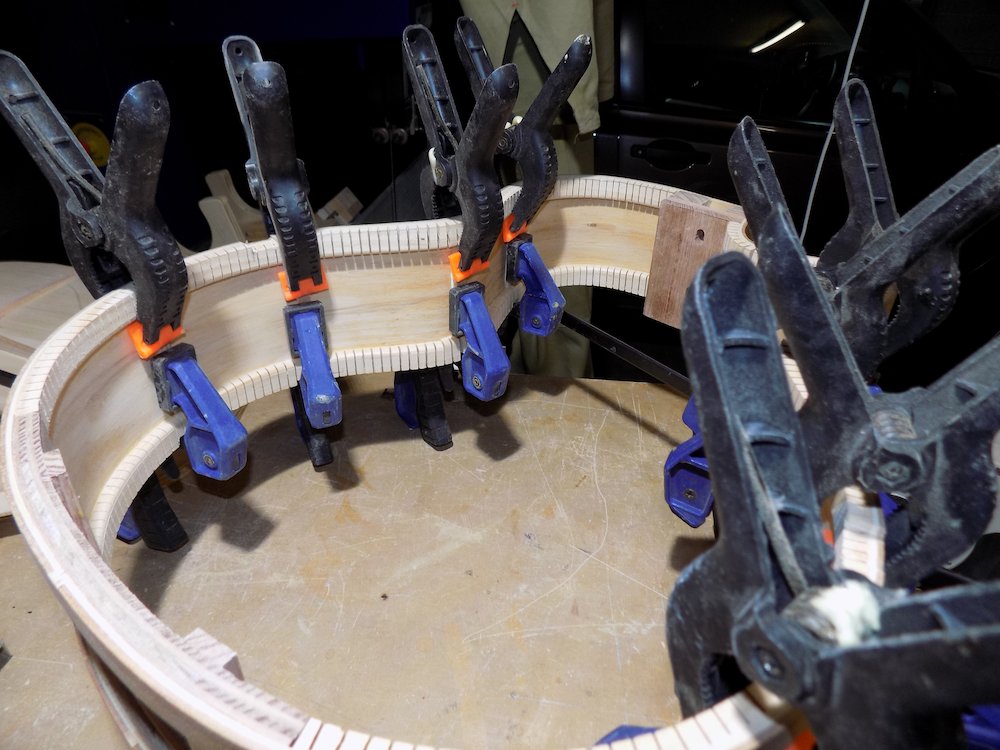

Cut and glue in place, top & back, clamping with washing clamps (see image)

NB: for inside the cutaway horn section, the kerfs will need to be widened with a file, beveling the blocks so they can pack closer together

Using the Shinto (not band-sander!) trim to a whisker above already-prepared top and bottom profiles, then sand by hand to get perfect surface for gluing

Kerfed lining stock milled |

Bandsaw jig for cutting kerfs |

Kerfed linings cut |

Bevelling the kerfed lining for the cutaway horn |

Gluing kerfed lining |

Sides levelled ready for soundboard and back |

Bolt-on neck experiment

When levelling the soundboard edges of the sides, we want the extended "tray" of the neck block assemble to slope upward slightly, corresponding to the tiny amount of curvature the soundboard will eventually have.

Current attempt: when extending the tray line along the length of the guitar, have it end 5mm above the tailblock edge.

This makes the cutaway a bit problematic - the sides have to be higher to "meet" the higher neck tray.

Solution not yet crystallised...

Resawing, milling, butt-joining back and soundboard

Raw minimum dimensions (cut longer and wider for jointing and positioning leeway)

Model |

Length |

Width |

Board width |

Bass |

570 |

460 |

230 |

GP |

500 |

410 |

205 |

Parlour |

470 |

390 |

195 |

both pieces, both sides

Mill timber to 5mm

Resawing on the bandsaw - use resaw post, lock the fence down proper!

NB: pay special attention to drum sander scarring: particularly if using 60-grit sandpaper.

If perfectly parallel to the grain it can be overlooked, but with any lateral movement in the drum sander it becomes an eyesore that is very difficult to sand out, particularly on the soundboard.

A combination of 80 grit, plus some final low-friction passes on the show face, should be enough to keep it under control.

NB: if not butt-joining immediately, store boards clamped between two flat boards to prevent bowing/cupping

Resawn boards for soundboard and back |

Soundboard and back boards drum thicknessed |

If necessary, joint the edges with jointer fence on router, although that can have tearout issues.

Preferred method: use aluminium angle jointer sanding jig.

Jointing the soundboard to prepare for butt-join |

Preparing to butt-joining the soundboard |

Butt-join using a sheet of MDF, nailed down strips of pine as edge stops

Cover MDF with oven paper where join line will be

Raise the two pieces along the join line with a piece of 19x42mm stock

Position and nail down edge stops

Apply glue, align, then remove the length of stock and press down

Check joint alignment, cover with more oven paper and weight

Butt-joining the soundboard |

Tracing the body shape to soundboard |

NB: after butt-joining, store boards clamped between two flat boards to prevent bowing

When dry, using mould, trace body shape outline, cut with bandsaw, 5-20mm outside line

Leave flat sections at each end, so they can be pushed through drum sander with a piece of 3mm MDF

Mill to required thickness using drum sander

First mill non-show faces so that join line is clean and smooth

Then mill show faces so that join line is clean and smooth

Finally mill non-show faces (again) to width

Soundboard:

Celery-top: 2.8mm

Huon Pine: 3.0mm

King Billy: 3.4mmBack: 3.5mm

Clearly mark centre lines

Body shape traced onto soundboard and back |

Soundboard and back outline roughly cut |

Bracing and fitting back and soundboard

Prepare (rip, resaw and mill) back-brace sizes and positions

Four,

two x 8*16mm (vertical taper, neck end)

two x 12*19mm (rounded over, tail end)

Spacing (from neck)

Bass |

110 |

95 |

110 |

110 |

leaving 130 to tail |

GP |

99 |

86 |

99 |

99 |

leaving 117 to tail |

Parlour |

93 |

80 |

93 |

93 |

leaving 110 to tail |

While thus tooled up, might as well mill stock for side braces as well

8x5mm, long enough for eight x body height

Bracing timber milled |

Bevelling bracing pass one |

Bevelling bracing pass two |

All bracing pieces sectioned |

Prepare A-frame soundboard braces size and positions

Two pieces, 8*19 (vertical taper)

from neck joint to a spread at tail of

Bass |

165 |

GP |

149 |

Parlour |

140 |

2 * 8*17..19 wing braces (rounded over) (outside of bridge to side)

Bass 165 |

GP 150 |

Parlour 140 |

Sanding profiles into braces

Rough-in the profile with belt sander

Use a holding jig to avoid stressing fingers

Make a small number of jigs with set-length adjustments (bolts screwing down)

Handles to hold easily and press while sanding

Clamp sandpaper to moulds, sand until full profile is cut (no flat spots)

If using the pinch handles, be very careful not to rock the pieces

Use the handles to apply back-and-forth pressure,

letting the pieces stay "seated" at all times

Bracing preparing to profile |

Profile rough-sanded into one of the braces |

Fine-sanding the profile to one of the braces |

Profiling finished on one of the braces |

Fine-sanding profile to one of the A-frame braces |

All braces profiled |

Planning back brace positions and gluing

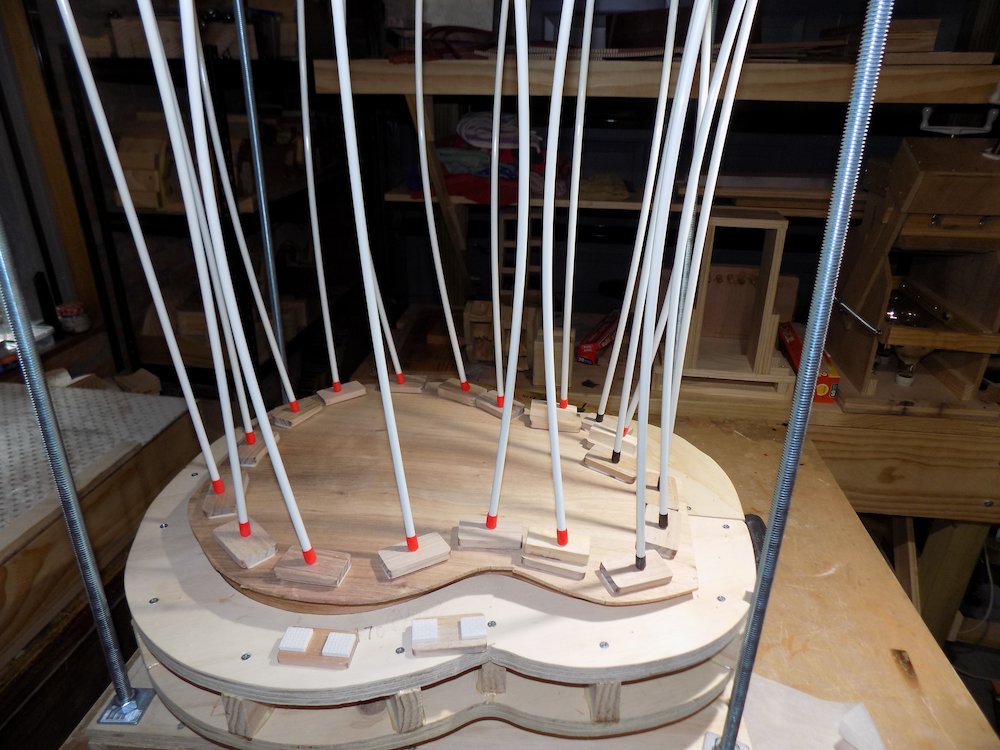

Method 1: (preferred) regular clamps at ends, caul blocks & go-bar clamps in middle

Method 2: (shown) caul blocks and go-bar clamp at ends first, clean up squeeze-out, then do middle

Enhancement: make two forked alignment guides that can be clamped to the edge, to prevent the pieces from wandering during before clamping is complete

Preparing and fitting centre-strips

Cut five lengths of milled 3-4mm cross-grain hardwood

30-40mm wide

NB: the outer two cannot be glued yet (length depends on neck block and access port)

The reason we glue the inner three pieces now instead of later is simply to make the back stronger during the next few steps

Round over edges, glue the inner three down centreline of back

Use go-bar clamps, same rods as for back braces (with 19mm cauls)

Gluing back braces |

Gluing (middle three) centre strips |

Tapering back braces

Spokeshave, plane, chisel, short block of scrap to check straight lines

Originally

Tail end pair: 50mm linear taper down to 2mm at perimeter

Neck end pair: 65mm linear taper down to 2mm at perimeter

Amended

taper down to 1mm, so that notches in sides can be covered by 7mm bindings instead of 9mm

Planning and gluing soundboard brace positions

Trickier

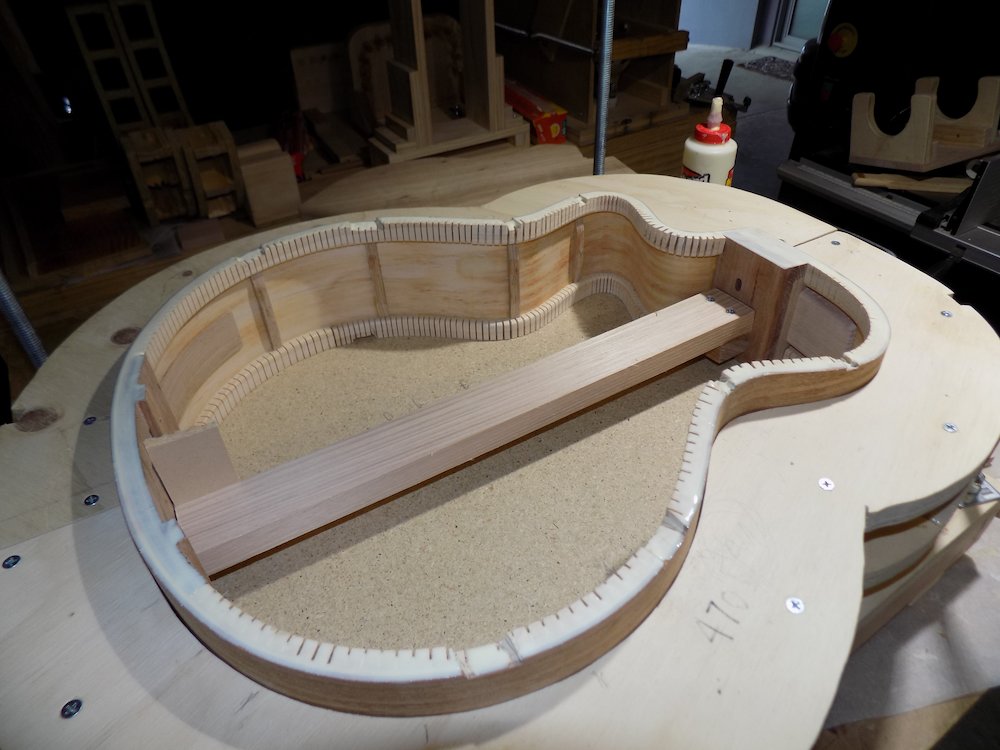

Put side frame in mould, with turnbuckle bracing if required

Trace out neck-block, cutaway-kerfed lining, access port positions - to the inside of the soundboard

Mark how A-frame braces need to trimmed to fit (and do so)

Glue: normal clamps at ends, go-bar clamps in middle as per when gluing back braces

Tapering soundboard A-frame braces

Taper full-scale line to neck,

then from 19mm tail-ward of that line to tail

(ie around the wing braces)

aim for 2mm at ends

Scalloping: about 5mm dip midway, both ends

Tapering back braces |

Fitting soundboard braces |

Gluing soundboard braces |

Tapering soundboard braces |

Preparing soundboard bridge plate

Body-fret to full-scale line

24.75 14-fret |

280.0 |

25.5 14-fret |

288.5 |

Bass 14-fret |

384.7 |

Mark bridge-line (full scale length)

Bass bridge is 52mm deep, guitars less than 50

- let's just say 50 for all

Cut 3mm bridge plate, 75mm deep (will trim later)

Cross-ply

Sand in a bit of a lateral crown to match dip in mould

(to reduce the bracing contours appearing when the soundboard is varnished)

Starting 7mm in front of bridge line, total depth = bridge_depth+10

60++ is probably about right

Experiment: try 57e

wedged between A-frame braces

Trim depth after getting the wedge angle right

Soundboard hole and neck-end support

Both: cross-ply for additional strength

Soundboard hole support: 2mm hardwood (can be multiple pieces)

hole support: bout to waist, board can be slipped under sides for tracing

For this operation, soundboard should "fit" against mould-encased side frame,

(which should already be traced on the inside of the soundboard)

Neck-end support: 4mm hardwood (back trimmings OK, can be multiple pieces)

NB: skip neck-end support for bolt-on neck option

Laminated below fingerboard on body, nestled in the top of the "A"

Bass: |

120mm |

12-fret 24.0": |

120mm |

14-fret 25.5": |

85mm |

14-fret 24.75": |

83mm |

14-fret 24.5": |

82mm |

Taper soundboard wing braces

cut bevel (optional compound / two-dimensional) so they sit against A-braces

They sit against the tail-ward side of the full scale line, straight out

Sand tiniest possible curve on bottom, then taper from top

Down to >1mm

Straight at first, then optionally with subtle scalloping

Glue in bridge plate, hole support, neck-end support and wing braces

Wing braces aligned with the 19mm full-height section of A-frame braces

Go-bar clamps/deck

Fitting bridge plate, soundhole support and neck support |

Gluing bridge plate, soundhole support, neck support and wing braces |

Preparing to fit back to sides

NB: fit sides into solera mould, it makes subtle differences to where we need to cut channels for the braces

Place access port cover in the hole (to support clamping)

will need to drill tail strap-button hole if not done already so that cover can be pulled out afterwards

put temporary 1/8" bolt & nut, protruding outwards as "puller"

Sides are in mould, turn-buckle clamps if required so no gaps

While "rolling" the back over the sides, mark where the braces meet the sides

Before cutting, fill in the kerfs around the marked positions with pine shavings and polyurethane glue

Try to have the filling just go down 5mm, so that the kerfs will look natural through the soundhole,

The idea is that the kerfs stop just before the bit that is to be cut away

This will prevent linings from crumbling when cutting channels

Now it is time to start cutting the channels

Start at one end, making sure both ends are centred

One brace at a time

Double-check position and alignment at every step

Cut brace channels too narrow, then check, then widen

Sand out incorrect pencil marks to avoid confusion

Cut small channels using small pull-saw, chisel and file

With the pull-saw, make two edge cuts,

make them too narrow at first - better to file outwards than have gaps

then two shallow wedge cuts to meet them,

then chisel out the "hill" in between

finally use chisel, file and sandpaper to create the "downward" ramps into the body

check position at each step

Adjust so that back can curve over sides, into place

NB: finish centre-strips at this stage

Trace neck block and access port edges onto inside of back

cut the final two centre strips to fit, glue them in and confirm that everything still fits

Cutting channels in sides for back braces |

Gluing outer two centre strips |

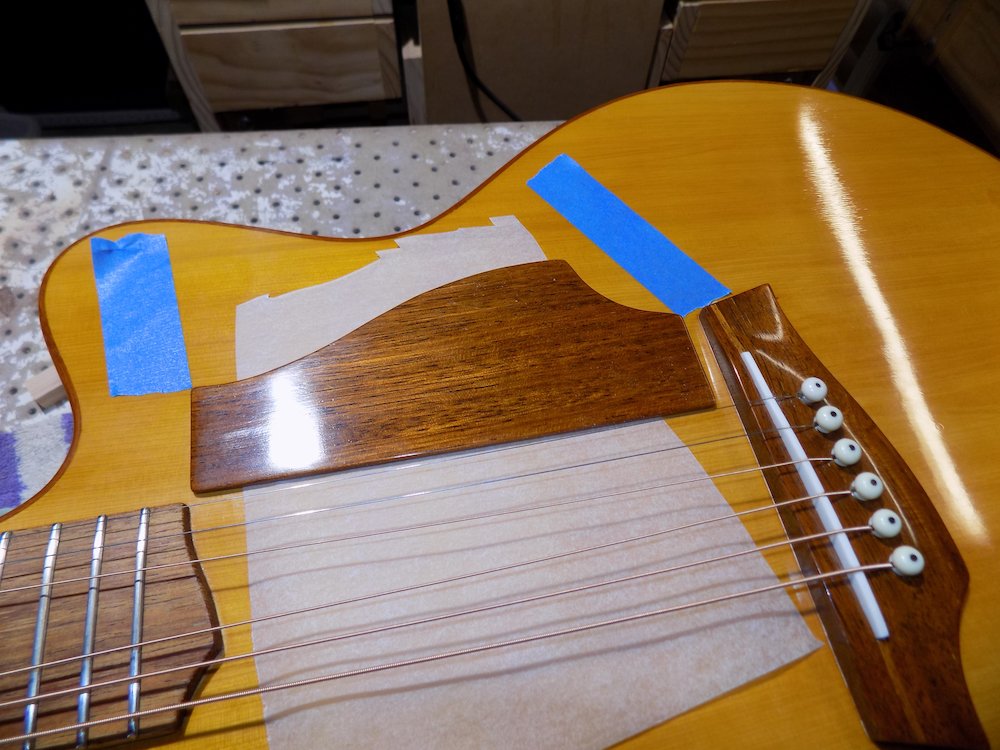

Preparing to fit soundboard to sides

Same deal - cut shallow channels for wing braces

Cut and fit vertical side braces

Takes sides out of frame for easier clamping

rip some hardwood 8x5mm

Same positions as back braces (slots in kerfed lining)

Cut to fit between kerfed linings

15mm taper to 2mm top and bottom

(dimensions not critical)

Cutting channels in sides for soundboard braces |

Gluing vertical braces |

Cut and fit support backing for pickup socket

use some spare curved hardwood stock (leftovers from access port?)

Cut and fit support backing for neck strap button

Cut a piece of hardwood about 55x55x10mm

Cut or sand to match curve "above" neck block

Nestle between curfed lining, and against neck block

Socket and strap-button supports cut |

Gluing socket and strap-button supports |

Socket support |

Strap button support |

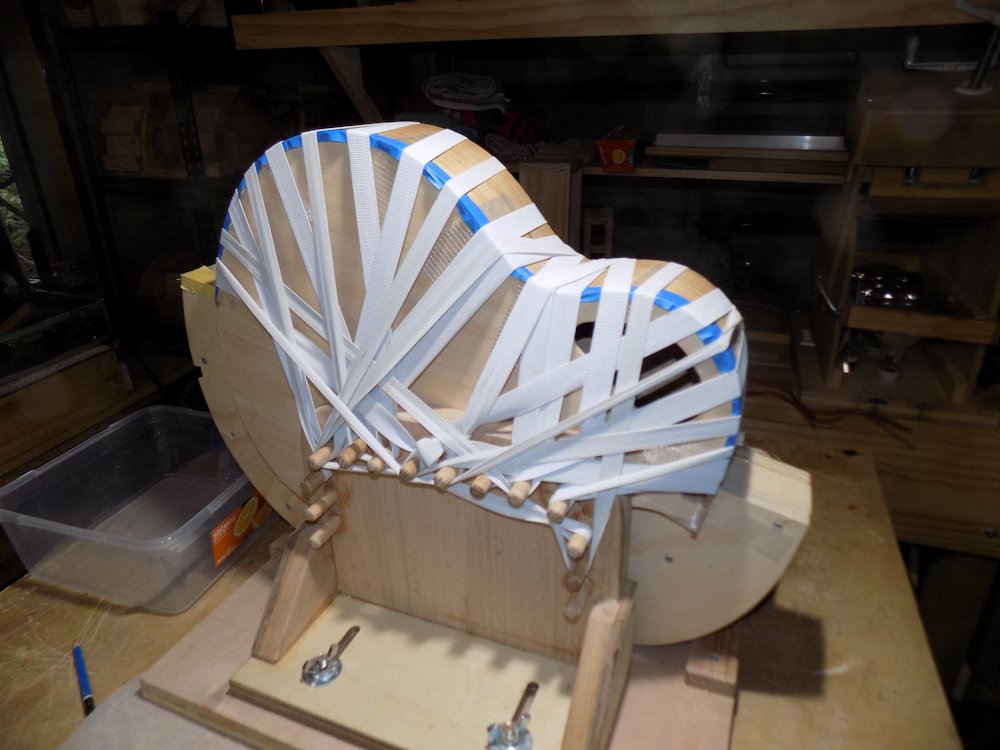

Glue back to sides

Back in frame with turnbuckles if required

Attach "rudder" to neck block, make sure it is perfectly square to centreline

Go-bar deck & rods with split-cushion cauls to distribute force

(avoid uneven joins, gaps)

Do a full dry clamp-up first, to check that all join-lines are tight.

if the end centre strip pieces are too long, the back can be glued properly at each end, but leave gaps around the cutaway area

Starting to glue the back, note rudder to align neck-block |

Clamping the back using Go-bar deck |

Glue soundboard to sides

NB: make sure the sides are square, so that the guitar can sit stable on its sides

Use wedged sticks if required,

to push top part of sides against mould

can't have turnbuckle clamps in mould when gluing top! (or can we? possible if exit stragetgy has been confirmed in advance!_

less force will be required, as final shape is fixed by glued-in bottom

we're only "tilting" the sides to their final shape at top

Go-bar deck & rods with split-cushion cauls to distribute force

Another thing to consider:

since the guitar is resting on its curved back, excessive force

when fitting soundboard may cause the sides to warp slightlyconsider supporting the sides (with pieces of varying thickness)

Bolt-on neck experiment

check alignment of fingerboard support tray and tongue

shim / pad / infill as required

Trim overhang carefully with flush-bearing router

**Climb-cut everything that's "flat"***

**For the rest, always go "downhill" (towards centreline)

Tear-out is a risk, especially if the bit is dull

(though small tear-outs will be covered by binding)

Make multiple 2mm climb-cut passes

Don't worry about 1-2mm overhang on back, due to curved back

it will be taken care of when cutting binding channels

Gluing the soundboard to the body |

Body fully enclosed for the first time |

Trace, cut and smooth soundhole

Trace outline using template as a guide

Positioning

outside of hole follows 25mm inside upper bout edge

inside of hole approaches fretboard by about 25mm (more for bass)

inside of hole forms a smooth curve with lower bout (below the waist)

that curve involves a slight angle between the straight sections of each side (hole, bout)

template may not be 100% accurate to achieve this

(Originally used Dremel with downmill)

Large diameter Forstner bit for initial hole, then small router, then Dremel with mini drum sander

then finish with sandpaper wrapped around PVC pipes of various diameters

Very slight roundover around the hole - large roundovers are harder to French polish

Rout (or cut with table saw) a vertical channel along the cutaway-neck "corner"

Decide on whether to do this now, or immediately following the binding channels

Now: tear-out is less of a problem, but the gap must be temporarily filled before cutting binding channels!

Later: no problem with binding channels around the heel, but tear-out is more of a problem!

Preferred: later, with a piece of sacrificial scap temporarily glued in to shore up against tear-outDecide on design:

Wider strip (show face at side, preferred) = best "enclosed" by bindings

Narrower strip (not preferred = bindings can butt up against it, in which case defer until after attaching bindings)10x3mm is OK, so is 2*2mm

Do not exceed 3mm "thick" - the channel depth must not extend beyond the binding channel!

Cut the strip and channel now, so that any tear-out will be removed when routing binding channels

We will glue the strip in after gluing the bindings

Use same wood as for bindings

For softer soundboards (especially Huon Pine)

Fit a soundboard protector for much of the rest of the build. It is so easy to scratch and dent!

Soundhole cut and sanded |

Cutting channel for cutaway-neck join strip |

From now on

Guitar body needs to rest on a towel to prevent scratches and dents

Before routing the binding channels

Check the sides for any waviness, and level them by aggressive sanding and scraping.

If not done so already, level access port cover at this time too

Seal a strip 25mm each side of the bindings edges with shellac (except heel-join area)

This is to prevent glue squeezeout from soaking in, which is otherwise discovered when French polishing, and has to be aggressively sanded backFor bolt-on neck option, seal a larger area - the only think we need to keep clear of is the bridge!

(Though keep it out of the vertical channel along the cutaway-neck corner)

Doing these steps after attaching the bindings risks having to scrape the bindings too far back, leaving uneven thickness.

Rout binding channels

Sharpen router bit first!

Rout to 3.5mm inward depth, 8-9mm downward depth

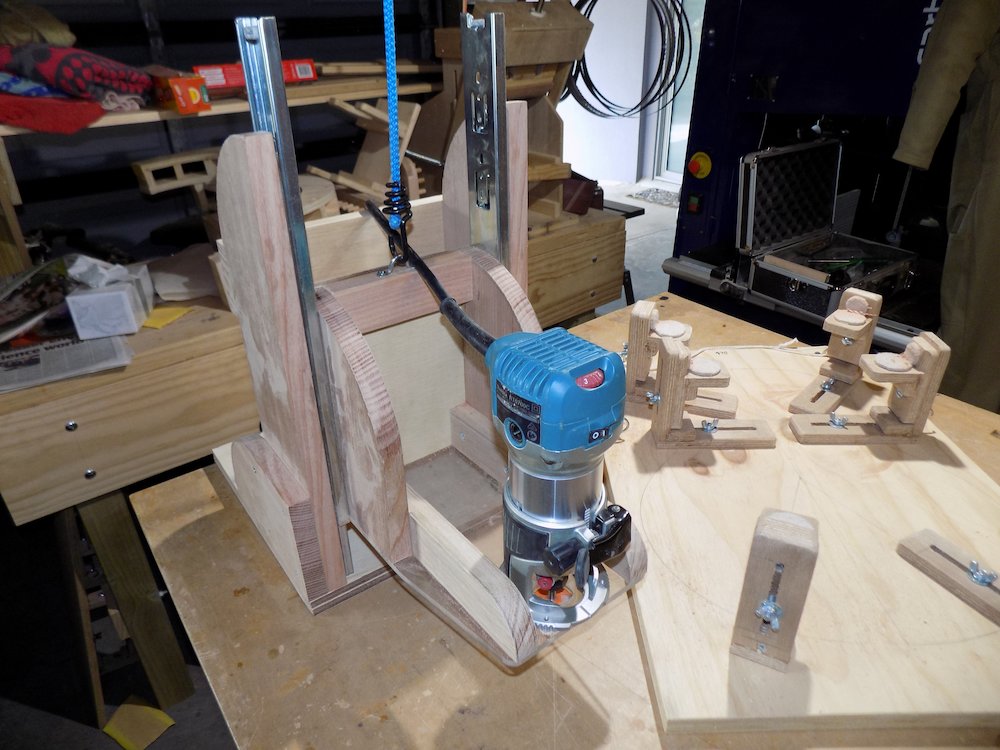

Use router with vertial sliding jig and rabbet bit w. bearing

NB: take care at the neck/cutaway corner - do not round it over! Keep it square!

NB: also, make absolutely sure the guitar body is straight and secured in the cradle, so the channels are perfectly vertical!

NB: also, check that the router is cutting channels to the full (sideways) depth - make sure the sides are against the roller bearing, and measure depth to confirm 3mm all around

Direction of cuts

Any cuts along slopes - cut "downwards", (ie, towards waist, towards centre)

Any other cuts - climb-cut

After everything is done, go around again in the regular push-cut direction to tidy things up

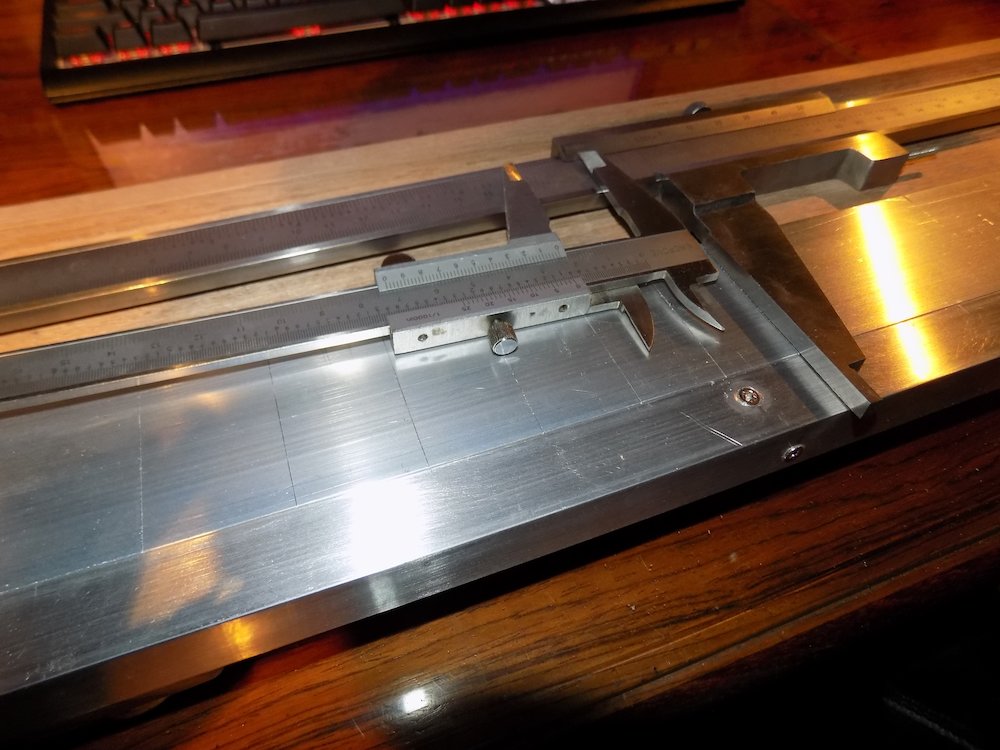

Tips for building jig

Similar to StewMac vertical sliding jig

use two drawer runners, wheels aligned back-to-front

the assembly turned out a bit heaver (hello over-engineering!), so I used a bungy cord to make it easier to use

for the "donut" to allow the jig to "ride" the sloping back edges, I used multiple layers of Perspex Araldited together

Router jig for cutting binding channels |

Cutting binding channels |

Rough-cut neck-tongue pocket

This must be done after the binding channels are cut, or there will be problems near the heel cap!

Open up a hole in edge with pull-saw

Use flush-cut router bit

Glue in the vertical boundary strip along the cutaway-neck "corner"

(Strip and channel may have been cut two steps earlier, otherwise do it now, with anti-tearout measures)

Scrape and sand flush (neck-facing side)

Leave a bit proud on the side-of-body side

(So that we can scape/sand flush after attaching the neck)

trim each end flush with the binding channels

Binding channels cut |

Gluing the vertical neck-body boundary strip |

Attaching bindings

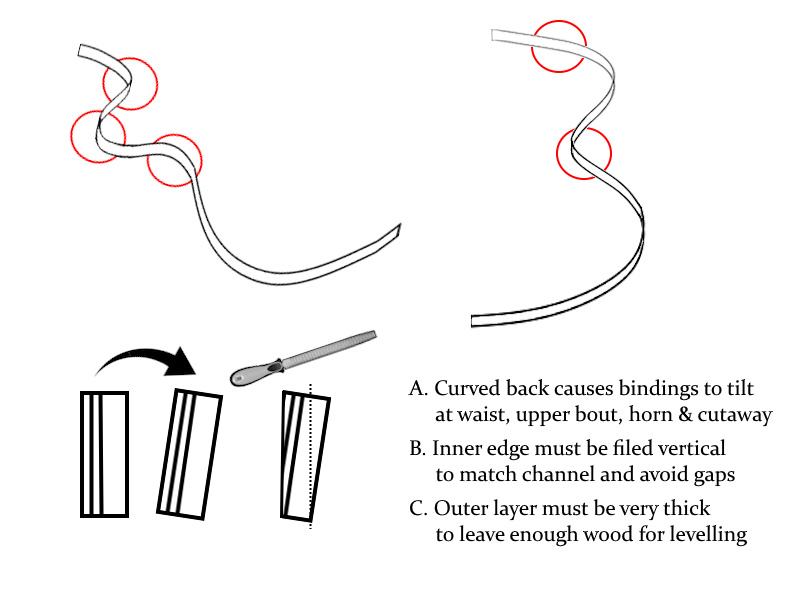

There is a problem with wooden bindings on a curved-back guitar, and I have yet to perfect a solution.

If using multiple layers of the same type of timber the problem is less severe, as the gaps can be filled

and are quite hard to see under shellac. However if using different timers for an accent strip,

the gaps are far more serious, as they cause the accent layer to visibly wander towards the edge.

Principles to solve this problem

use thinner inner layers so they will conform more easily,

use a bending iron on the thick outer layer, so that if perfectly conforms to its intended shape at rest.

make sure curved back profile is smooth, with no "sharp" bends

choose less-deep bindings, eg 8mm instead of 9mm

channels need to be perfectly vertical: make sure guitar is secure in cradle when cutting bindings channels so it doesn't tilt over

file/sand tilt-bevels (aka fillets) on inside surface at waist, upper bout, horn and cutaway so tilted binding presents a vertical face to glue

sandpaper and scaper seem to be the best way to do this

do at least one dry tape-up to test that tilt-bevels are adequate before gluing

Bindings tilt |

My first few guitars used two same-colour layers of ~1.7mm thickness.

However I now prefer to use two different timbers so we can have a "purfling-like" accent colour.

current practice

Soundboard side

Lighter-coloured soundboard makes a three-layer plan (dark/light/dark) more appealing

No curvature means far less risk of gaps around waist & cutaway

Inner layer: dark, 0.5..0.7mm

Middle layer: light: 0.5..0.7mm